Filament Change For Filament Runout Detection (FRD) Feature

| Model | [•] AON M2+ (CE) | [•] AON M2+ (R-NZ) | [•] AON M2+ | [•] AON-M2 2020 | [•] AON-M2 |

| Category | [ ] Installation | [•] Operation | [ ] Maintenance |

Summary

The procedure that follows gives instructions on how to use the Graphical User Interface (GUI) Wizard when the FRD Feature has been triggered:

- Remove the filament from the feed path.

- Change the roll of filament.

- Put the filament into the feed path to return the machine to service.

Estimated time: 15 minutes

Tools

| Qty | Description | Specification |

|---|---|---|

| 1 | Wire Cutters | N/A |

Parts Information

| Qty | Part Number | Description |

|---|---|---|

| A/R | Filament, Roll | N/A |

Reach out to our Customer Success team at help@aon3d.com to purchase rolls of filament.

Return to Service

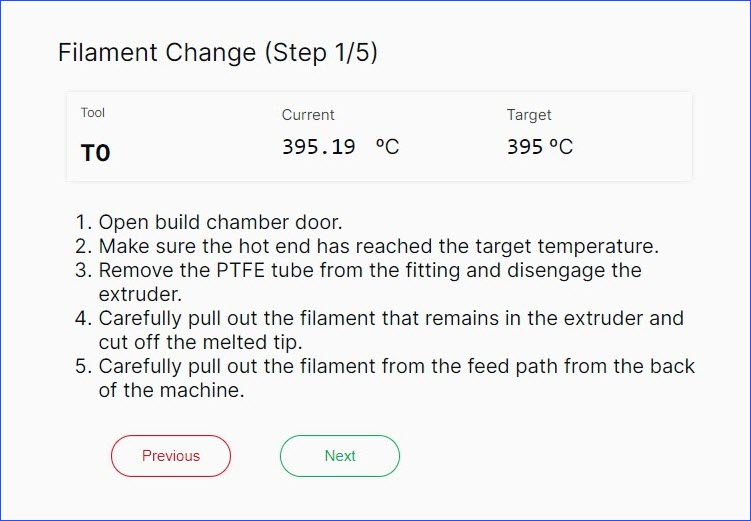

Do not touch the hot end(s) when toolhead heater(s) are ON. The temperature(s) in the hot end(s) can range from 200°C-450°C (390°F-840°F) and can cause injury if touched.

When there is no filament in the selected feed path, the steps that follow occur:

- The filament runout sensor tells with the Filament Runout Detection (FRD) Feature that there is no filament.

- The FRD Feature automatically pauses the print.

- The GUI tells the operator that there is no filament in the feed path.

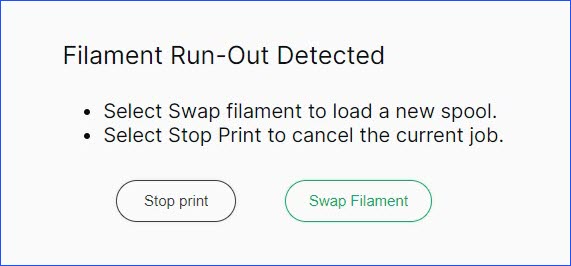

- The GUI gives the operator the choice to Stop Print or Swap Filament.

- The GUI gives the operator the choice to Stop Print or Swap Filament.

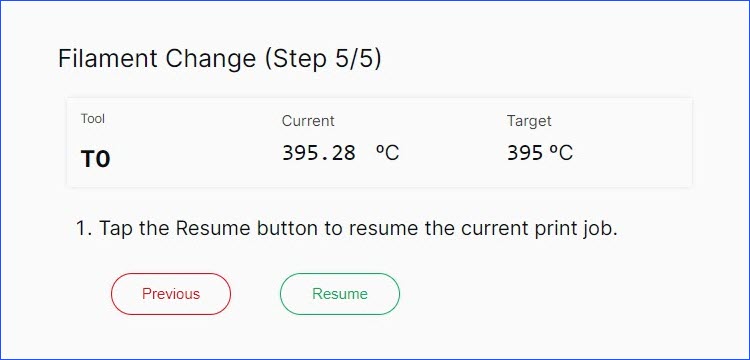

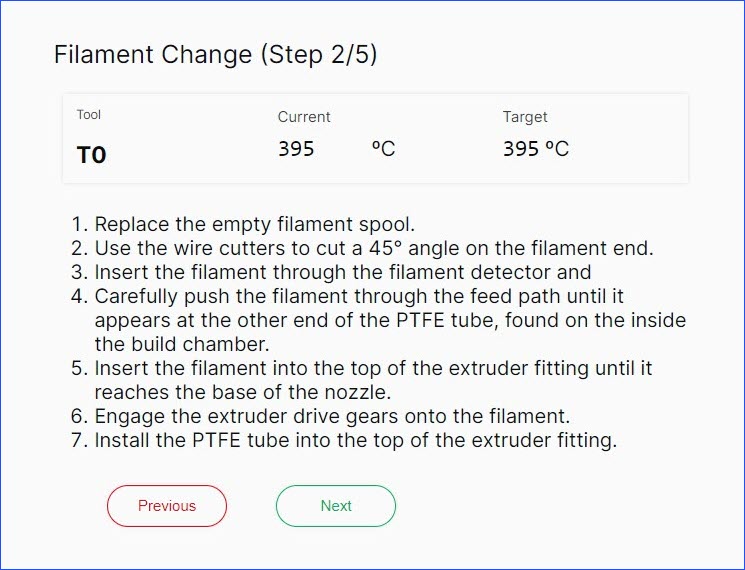

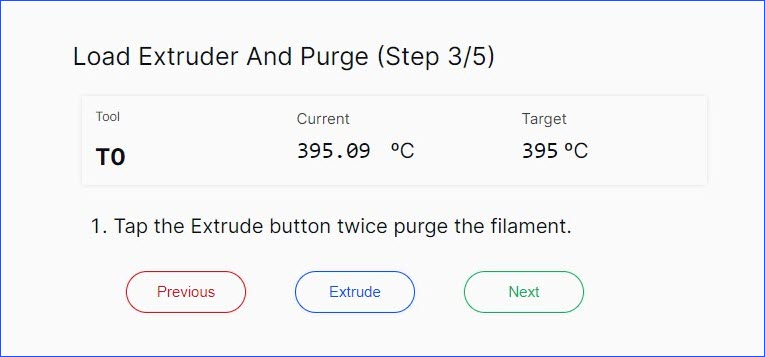

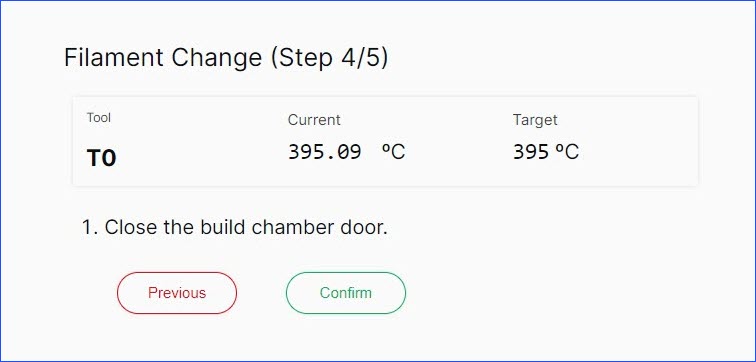

- After the operator has selected Swap Filament, the GUI instructs the operator on how to change the roll of filament.

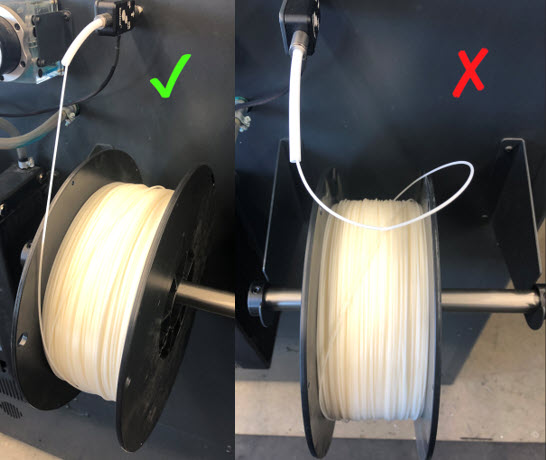

Make sure the roll of filament is positioned as such that the filament is looped, and fed, from the back once installed. Incorrect orientation will cause print failures and/or damage to the feed path.

- The machine can now be returned to service.