Ultimaker Cura

Summary

This guide is intended to help set up the Ultimaker Cura slicing software for use with the AON3D machine, and contains a few tips for using the slicer software with your AON3D machine.

How to set up Ultimaker Cura for the AON3D Machine

AON3D does not officially support the Ultimaker Cura slicing software. AON3D cannot guarantee that the use of Ultimaker Cura will not damage the AON3D machine and/or give the print results that SuperSlicer and Simplify3D® offer.

Prerequisite

Download the Ultimaker Cura software.

Adding a New Printer

- Under Settings > Printer, click Add a Printer.

- Under Add a non-networked printer, select Custom > Custom FFF printer. Name it and select Add.

Machine Settings

-

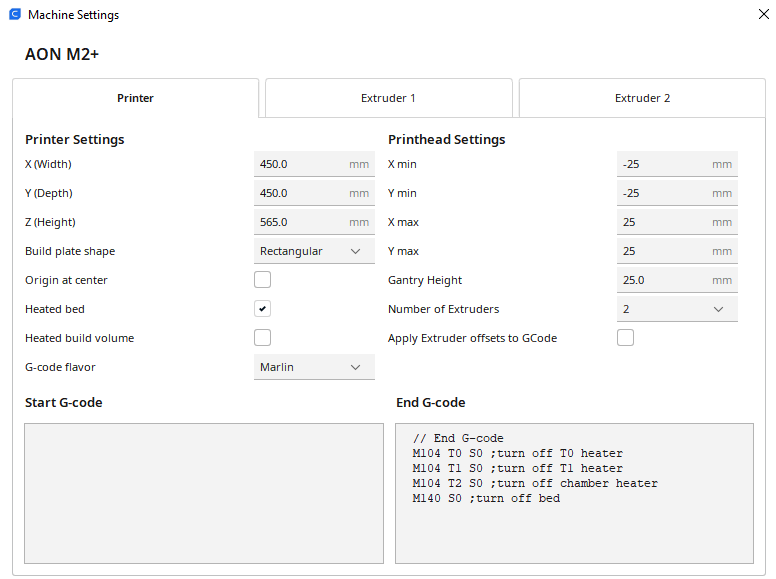

Fill in the Ultimaker Cura machine settings as shown below:

For AON-M2 and AON-M2 2020 machines, set the Z(Height) to 640 mm.

-

Keep the Start G-Code script entry empty.

-

The recommended End G-Code script commands is as follows:

// End G-code M104 T0 S0 ;turn off T0 heater M104 T1 S0 ;turn off T1 heater M104 T2 S0 ;turn off chamber heater M140 S0 ;turn off bed -

The Printhead Settings distances are conservative to avoid collisions with the cooling tubes on the toolhead. This is only relevant when printing multiple parts one after the other, rather than layer-by-layer. Refer to Multi-Part Printing for additional information and details.

-

The user should not check the Heated Build Volume” box, as Ultimaker Cura uses a different G-code command

M141for a heated build chamber than the AON3DM104 T2. The user must manually set the build chamber temperature. Although the AON3D machine should already be set to the correct build chamber temperature before a print is started, the user must make sure that the temperature is correctly set. The user can use the End G-code script in Ultimaker Cura to power the build chamber heater OFF at the end of the print, just as with Simplify3D®.

Extruder Settings

-

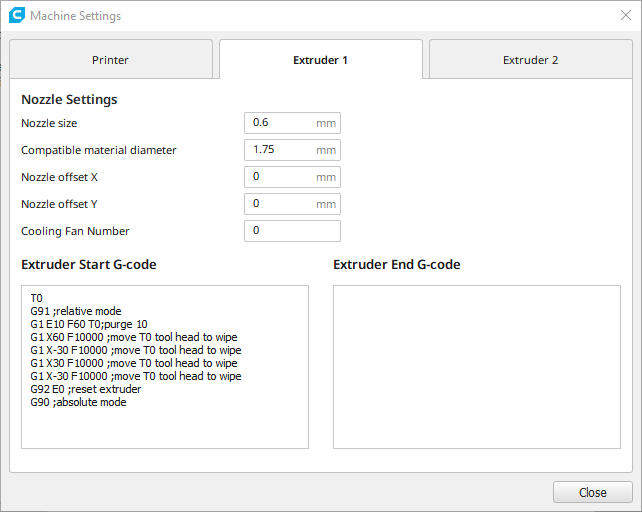

Set the nozzle size diameter for each hot end assembly.

-

Enter the 1.75mm filament diameter.

-

For the Start G-code and End G-code scripts, you can enter our generic Tool Change Scripts for T0 and T1 (copied below). Note that the material profiles we provide for Simplify3D® often have optimized versions of this script for specific materials and nozzle sizes. AON3D recommends checking the Tool Change Scripts in Simplify3D® to replicate them in Ultimaker Cura per material.

// T0 Start G-code T0 G91 ;relative mode G1 E10 F60 T0;purge 10 G1 X60 F30000 ;move T0 tool head to wipe G1 X-30 ;move T0 tool head to wipe G1 X30 ;move T0 tool head to wipe G1 X-30 ;move T0 tool head to wipe G92 E0 ;reset extruder G90 ;absolute mode // T1 Start G-code T1 G91 ;relative mode G1 E10 F60 ;purge 10 G1 X-60 F30000 ;move T1 tool head to wipe G1 X30 ;move T1 tool head to wipe G1 X-30 ;move T1 tool head to wipe G1 X30 ;move T1 tool head to wipe G92 E0 ;reset extruder G90 ;absolute mode

Notes for Use

G-Code and M-Code Commands

The AON3D machines use custom firmware. Ultimaker Cura uses several G-code and M-code commands that are not supported on the AON3D firmware. The user will be alerted on the Graphical User Interface (GUI)/web browser when one of these commands is encountered, and the command is ignored. Generally, these commands are not necessary and ignoring them has no negative consequence, however AON3D cannot guarantee this is always the case.

Known unsupported M-code commands used by Ultimaker Cura:

- M105

- M107

- M141

Refer to the Program Codes Guide for information on all the G-code and M-code commands used to operate the AON3D machine.

Settings

Most settings can be manually transferred between SuperSlicer or Simplify3D® and Ultimaker Cura, although many have different names. Ultimaker Cura also tends to break down settings into more granular options with more levels of control but does not filter for relative usefulness of these options or how best to combine them.