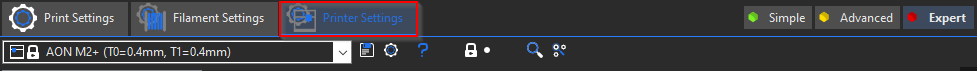

Printer Settings

The Printer Settings tab generally includes all the hardware-related settings that are specific to the printer. These settings include nozzle size, build volume, extruder capabilities, machine limits, acceleration and feed rates, and the firmware. Most of the settings under this tab require No Change by the user, as they are set by the AON3D team according to the AON M2+ specifications. However, there are some settings that the user will be able to modify and change as they see fit according to model and print requirements. This document covers the settings that are most common to modify or that user could change as per their requirements.

The top left of the window contains the drop-down menu, from where the user can select the T0 and T1 nozzle sizes. Similar to the drop-down on the left panel of the main UI. Make sure to have the same selection on both the UI and the individual tab. They may not necessarily be identical.

Once the desired nozzle size combination is selected, the tabs under Printer Settings will update to our standard presets. Click on each tab to see the setting options. Below are the settings one may require to change more common basis.

Custom G-code

This tab allows the user to add custom G-codes at the Start and End of a print as well as between layers, Tool changes, or Objects if there are multiple objects.

Similar to the preset G-codes, add a description separated by a ; for each command in order to reference back to it later.

Do not add filament-specific G-codes in this section as they have their own space under Filament Settings.

Extruder 1 & Extruder 2

Extruder 1 and Extruder 2 tabs refer to T0 and T1, respectively. The setting options are the same, as follows.

Tool name

Nozzle diameter

These settings do not require change, unless to add a new nozzle diameter that is not existing in the drop-down.

These settings define the limits of possible layer heights throughout the print for the selected nozzle. Including default, first layer, bridging, etc.

Min and Max layer height values could be expressed in absolute values in [mm] or a percentage (%) of the nozzle diameter.

During travel moves (movement of the toolhead from one point to another without extruding material), the extruder pulls filament back from the hot end and then returns to its original position at the start of the next extrusion move. This is to reduce melt leakage from the nozzle tip, which contributes to print artifacts such as “oozing” or “stringing”. This behavior is referred to as Retraction.

Length: This is the length in [mm] of the untreated filament that will be pulled back at retraction points.

Lift Z: This setting lifts the hot end X [mm] up from the part at retraction points. This setting helps avoid the deposition of melt leakage, if any, at the retraction point.

Minimum travel after retraction: This defines the minimum travel required for activating retraction. The travel allowed should be short enough to avoid material leakage.

Retract on layer change: If this setting is enabled, retraction will activate on every layer change. This may not always be necessary.

Oozing and stringing could be the result of both nozzle and material characteristics. Therefore, the ideal retraction setting depends on the features of both of these components, but is more dependent on the material. To account for this dependence, there are additional retraction settings under Filament Settings that will override the above settings, if activated.

A short description of each setting on SuperSlicer is available by hovering the cursor over the setting name. To learn more, PrusaSlicer’s documentation contains useful pages on specific slicer settings.

Basic slicing support is available to all AON3D customers. For advanced support inquiries, an AON3D success plan may be required. Our Success plans help businesses get started fast, minimize downtime, and quickly become experts in industrial additive manufacturing.

Contact us at help@aon3d.com to get started or for Success Plan information.