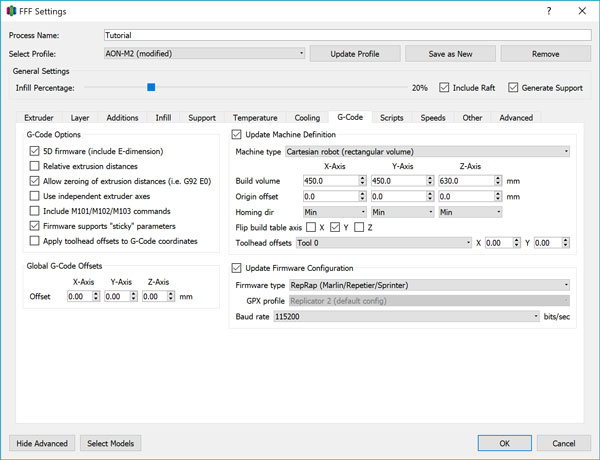

G-Code Tab

Most of the options on this screen should be set once during initial configuration and then left alone.

G-code Options

5D Firmware

Provides support for X, Y, Z, F (speed), and E (Extrusion distance) parameters in G-code. Keep this on.

Relative Extrusion Distances

Affects the default behavior of the E-axis - whether the extrusion distance counter is cumulative or not. Keep this off.

Allow Zeroing of Extrusion Distances

Allows the E counter to be reset to 0. Keep this on.

Use Independent Extruder Axes

Certain firmwares track the extrusion rates individually. Keep this off.

Include M101/M102/M103 Commands

Provides support for legacy G-code commands, not used in modern 3D Printing firmwares. Keep this off.

Firmware supports Sticky Parameters

Sticky parameters allow non-explicit declaration of speed parameters. Keep this on.

Apply Toolhead Offsets to G-code Coordinates

Enables use of the Toolhead Offsets feature in Simplify3D. Keep this off.

Global G-code Offsets

Provides a virtual co-ordinate offset to compensate for hardware changes. Keep these each at 0.00; these adjustments are made using software.

Update Machine/Firmware Definition

If you are running several different 3D printers, check this option to have Simplify3D® automatically update the basic configuration via the process settings instead of manually inputting the changes every time.

Machine Type

Selects either Cartesian (XYZ rectangular) or Delta (circular) configurations for the 3D printer. Set to Cartesian.

Build Volume/Origin Offset

Sets the build volume of your printer, updates the size of the virtual workspace accordingly. Set X, Y, and Z with the machine specific values below. No origin offset is necessary for the AON-M2 as this is set in the firmware.

- X: 450 mm

- Y: 450 mm

- Z: 565 mm

- X: 450 mm

- Y: 450 mm

- Z: 640 mm

- X: 450 mm

- Y: 450 mm

- Z: 640 mm

Homing Direction

Which direction the axes move to go to the zero/home position. All axes should be set to Min.

Flip Build Table Axis

Sets the positive/negative directions for the axes. Y should have a flipped axis, default for X and Z.

Toolhead Offsets

For multiple extruders, sets the offset distance between them, using Tool 0 as the (0,0) origin. The AON-M2 handles tool changes at the firmware-level. Do not use this feature.

Firmware Type

Sets the class of firmware and corresponding compatibility with G-code. Set to RepRap.

Baud Rate

Sets the serial USB bitrate. Set to 250000.