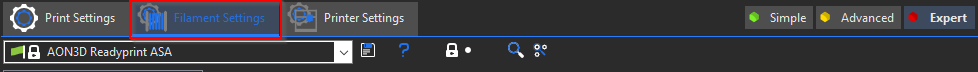

Filament Settings

The Filament Settings tab includes AON3D-validated filament-specific settings. Once SuperSlicer is successfully installed and AON3D’s configuration is added, the user has access to all AON3D validated profiles, including those of AON3D Readyprint™. These settings mainly include filament information (cost, density, etc), temperatures, retraction, etc. In this document covers the more critical settings.

It is possible to use filaments other than those listed in the AON3D configuration. Similar material profiles can be used as a basis to create a new profile for a new filament and save it for future projects.

The top left of the window contains a drop-down menu, from where the user can select the filament, similar to the drop-down on the left panel on the main UI. Always make sure to have the same selection on both the UI and the individual tab.

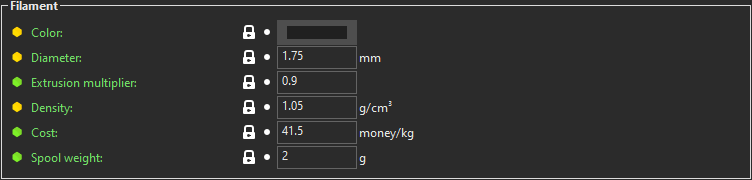

Filament

Color: This setting allows to change the color of the filament.

Extrusion multiplier: The extrusion multiplier is a set number for material type that is calibrated for all AON3D filaments. This number can be adjusted to compensate for over or under extrusion.

Density: This number does not change slicing behavior, but it affects the weight estimates. This should only be changed when adding a new filament.

Cost: Similar to density this only needs to be changed when adding a new filament to calculate the cost of the print. This number is dollar per kg.

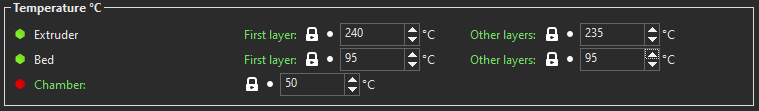

For each of the materials that comes with the AON3 Super Slicer version, the set temperatures should not be changed. Bed and chamber temperatures are taken from the material settings on T0.

Extruder This changes the temperature of the extruder for this material. Note that if this setting is modified, the first layer temperature should be slightly higher to increase bed adhesion, within +/- 30°C of the recommended set temperature.

Bed This changes the bed temperature for this material. Note that if this setting is modified both first layer and other layers should have the same bed temperature and no more than 20°C +/- of the recommended set temperature.

Chamber This sets the chamber temperature for this material. Note that changing the chamber temperature should be no more than 10°C +/- of the recommended set temperature.

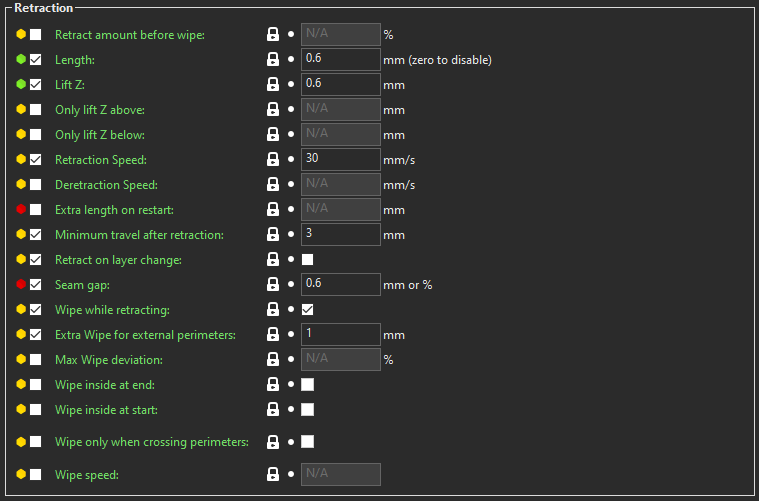

Filament Overrides

Settings under this section override similar settings anywhere else on the slicer, if selected. This is very useful for settings such as Retractions that are more material-dependant.

These settings should only be tweaked if needed, as for each material all settings have been calibrated and tested.

Length: This is the length in [mm] of the untreated filament that will be pulled back at retraction points.

Lift Z: This setting lifts the hot end X [mm] up from the part at retraction points. This setting helps avoid the deposition of melt leakage, if any, at the retraction point.

Retraction Speed: How fast the extruder retracts the filament in [mm/s].

Minimum travel after retraction: This defines the minimum travel required for activating retraction. The travel allowed should be short enough to avoid material leakage.

Retract on layer change: If this setting is enabled, retraction will activate on every layer change. This may not always be necessary.

Seam Gap: Coasts by a set [mm] after loop to avoid seams.

Wipe while retracting: Moves the nozzle while retracting to minimize chances of blobs.

Extra Wipe for external perimeters: Moves the nozzle by a set [mm] into the print at the end of a perimeter.

Custom G-code

This tab allows the user to add custom G-codes at the Start and End of a filament. This code will run before and after this material is printed including tool changes. Any filament-specific G-code could be added to this section. Add a description separated by a ; for each command to reference back to it later.

A short description of each setting is available on SuperSlicer by hovering the cursor over the setting name. To learn more, PrusaSlicer’s documentation contains useful pages on specific slicer settings.

Basic slicing support is available to all AON3D customers. For advanced support inquiries, an AON3D success plan may be required. Our Success plans help businesses get started fast, minimize downtime, and quickly become experts in industrial additive manufacturing.

Contact us at help@aon3d.com to get started or for Success Plan information.