Inspect Y-Axis Idlers Belt Movement

| Model | [•] AON M2+ (CE) | [•] AON M2+ (R-NZ) | [•] AON M2+ | [•] AON-M2 2020 | [•] AON-M2 |

| Category | [•] Preventive | [ ] Corrective | |||

| Frequency | [ ] Daily | [•] Weekly | [ ] Monthly | [ ] Yearly | [ ] As Needed |

Summary

The procedure that follows gives instructions on how to inspect the two Y-axis idler tensioners.

Estimated time: 30 minutes

Y-axis idler tensioners in good condition prevent:

- Rough belt operation that can cause belt damage.

- Unsatisfactory print layers.

- Unwanted loud noises and vibrations during movement.

Tools

None required.

Parts Information

None required.

If the machine is presently equipped with the older version of the Y-axis idlers, AON3D recommends upgrading to the Y-Axis Idler Field Upgrade Kit (K-0302-003). This kit includes two Y-axis idler assemblies that will greatly improve the print quality and overall machine reliability. The Y-Axis Idler Field Upgrade Kit (K-0302-003) is offered to all AON-M2 and AON-M2 2020 owners, at no cost, as a one-time upgrade when upgrading from the original Y-axis idler assembly only. Reach out to our Customer Success team at help@aon3d.com with your company name and machine serial number (the identification plate is found on the rear panel of the machine).

Personal Protective Equipment

| Qty | Description | Minimum Specification |

|---|---|---|

| 1 | Safety Eyewear | ANSI/ISEA Z87.1 |

| A/R | Nitrile Gloves | ISO 2859-1 or ASTM D6319 |

Prepare the Machine

Make sure that there are no prints on the build surface. Remove print(s) before the procedure that follows is started. Failure to do so can cause a collision and cause damage to the machine component(s).

- Home XYZ.

- Lower the Z-axis by 300 mm.

- Open the build chamber door.

- Push the E-stop button.

- Wait until the build chamber, build platform and hot ends are at room temperature.

- Inspect and adjust the Y-axis belt tension. Refer to Inspect and Adjust XYZ-Axes Belt Tension.

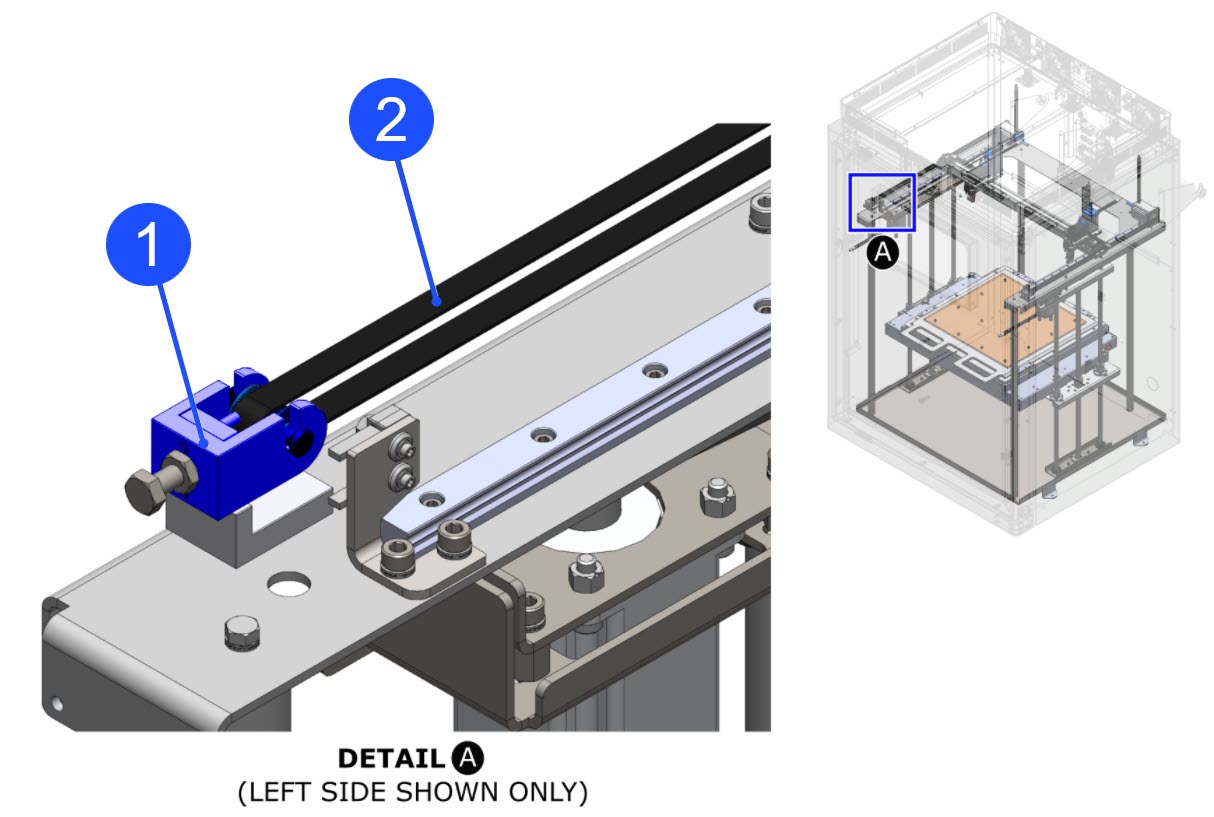

Inspect the Y-Axis Idler Pulley Assemblies

Wait until all machine components are at room temperature before you continue. Some machine components can be hot if the machine was recently used. Failure to do so can cause injuries.

- Manually push the Y-axis gantry to the back of the machine. Make sure that:

- The left and the right Y-axis idlers (1) turn smoothly.

- There are no unusual noises and/or vibrations from the left and the right Y-axis idlers (1).

- The movement of the Y-axis belt (2) is smooth and does not rub with machine components.

- Manually pull the Y-axis gantry to the front of the machine. Make sure that:

- The left and the right Y-axis idlers (1) turn smoothly.

- There are no unusual noises and/or vibrations from the left and the right Y-axis idlers (1).

- The movement of the Y-axis belt (2) is smooth and does not rub with machine components.

- Do steps 1 and 2 three times.

- Make sure that there is no damage on the Y-axis idler pulley (1) and the Y-axis belt (2).

- Replace components if necessary:

- To replace the Y-axis idler pulley(s), refer to Replace Y-Axis Idler Pulleys.

- To replace the Y-axis belt(s), refer to Replace Y-Axis Belts.

Test and Return to Service

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.