Frequently Asked Questions

Summary

This section covers the most frequently asked questions in regards to AON3D and its products. Click on the question to show the answer.

Build Plates & Bed Adhesion

First layer adhesion can be improved by verifying the build surface and modifying print process parameters in Simplify3D®.

Build surface verifications/suggestions:

- Verify that you are using the recommended build sheet corresponding to the material you are printing. Refer to the Material Guides page.

- If applicable, ensure any films have been removed from the build sheet before use. These films will not allow the filament to adhere to your print surface.

- Ensure the build sheet is clean.

- The Nano Polymer Adhesive can be applied to increase build platform adhesion.

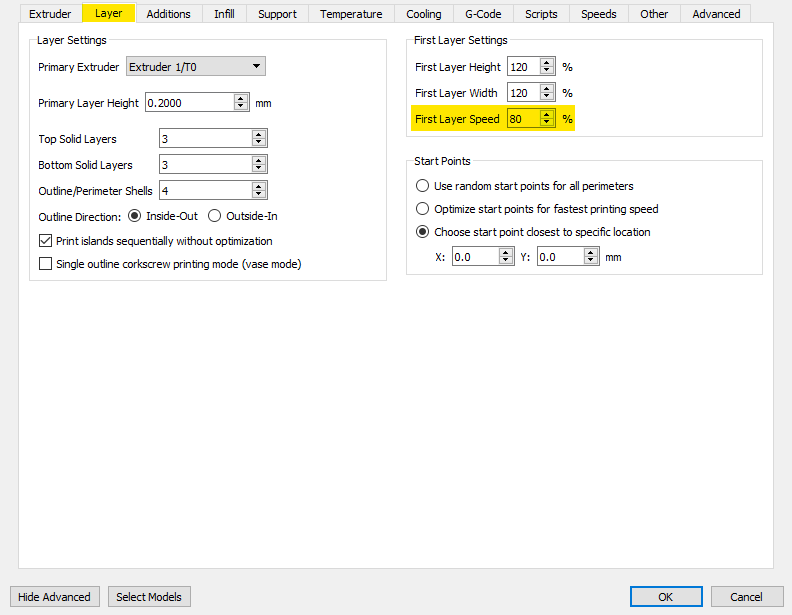

Simplify3D® print process parameter suggestions:

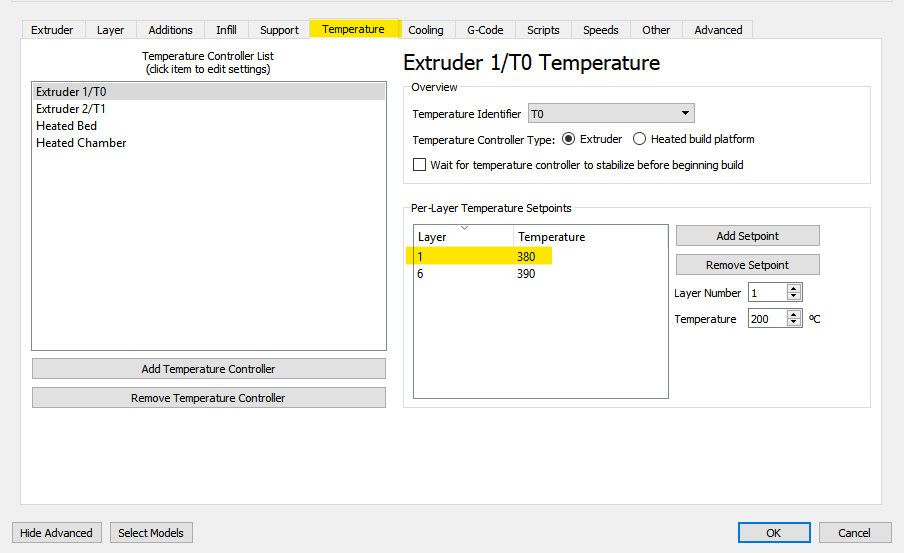

- Increasing the Extrusion Temperature for the first layer.

- Reducing First Layer Speed.

- Set your First Layer Height and First Layer Width to 100-150%. This will help deposit more material down on the build sheet and increase adhesion.

- Decrease the Z-axis offset. This helps for the same reason as point 3.

Refer to the Build Platform Adhesion page.

Some build sheets have protective films on them. Remove the protective films on both side of the the Polycarbonate (PC) build sheets.

For AON-M2 and AON-M2 2020 machines

PEKK, PEEK, and other high-temperature materials should only be printed on the High-Temperature Build Plate. The temperatures used for these materials are too high for the low-temperature build plate and its Kapton® tape. Only materials with a low extrusion temperature (under 260°C) should be printed on the low-temperature build plate.

For AON-M2 and AON-M2 2020 machines

PEI and aluminum have different coefficients of thermal expansion. When heated, they expand at different rates and to different total volumes. To keep the PEI plate as flat as possible against the aluminum base plate, the PEI plate is fixed into position with 16 bolts. This helps control the natural deformation of the PEI plate but also produces stress in the plate. To relax this stress, the PEI plate is annealed in place with the bolts. This process involves a slow temperature ramp-up, followed by a period held at max temperature, which helps to relieve stress in the expanded state.

The stress in the plate is significantly reduced by annealing but will still cause small cracks around the bolt holes - this is normal, and the cracks are much smaller than those formed when heating without annealing. We have found that this annealing process protects the plate from any significant future cracking. The plates we use in-house have been thermally cycled daily for 8+ months and have shown only very minimal signs of additional cracking. Sometimes the cracking may change over time, and that is normal.

To assess your build plate, refer to the Inspect and Clean Build Plate procedure.

If the PEI plate is damaged significantly, it will need to be replaced.

If the damage is insignificant, it can be resurfaced using the Resurface High-Temperature Build Plate procedure.

For AON-M2 and AON-M2 2020 machines

Selecting which build plate to print on is crucial to ensure proper adhesion of your print to the build plate. If a print does not stick well, you may run the risk of having a failed print.

When printing with low-temperature materials (extrusion temperature <260°C), the low-temperature build plate is recommended. The High-Temperature Build Plate can also be used for printing low temperature materials.

When printing with high-temperature materials, the High-Temperature Build Plate is recommended.

For material-specific recommendations, check out our Material Guides.

For AON-M2 and AON-M2 2020 machines

No. Our High-Temperature Build Plate has good compatibility for all AON3D-validated materials.

Yes. However, AON3D can only provide support with prints printed on genuine AON3D build plates.

For AON-M2 and AON-M2 2020 machines

No. Your print will not stick to bare aluminum. Ensure you have a proper surface coating, such as Kapton® Tape to make sure the polymer to sticks to the plate.

For AON-M2 and AON-M2 2020 machines

You may be printing too slow and/or at too high of a temperature. Check your slicer settings to avoid future recurrences of this nature. First layer speed can be adjusted in the Layer tab in Simplify3D® and you can add a different temperature set point for the first layer in the Temperature tab.

Hardware

There are several factors that will impact the lifetime of a hot end assembly which can lead to filament leakage.

Some of these factors are as follows:

- The print temperature(s) used.

- Print speeds and other settings include leaving the machine at temperature for too long, incorrect print settings, and/or printing at incorrect print speeds.

All lubricants used on the AON3D machines have been tested for their chemical capability with respect to their specific motion components. The use of alternate lubricants may damage the AON3D machine components and void the warranty.

| Motion Component | Product |

|---|---|

| X/Y-Axes | Krytox™ GPL225 Grease |

| Z-Axis | SuperLube Silicone Lubricating Grease with Syncolon® PTFE Grease |

| Extruders | Loctite® LB 8042 |

Specific instructions for lubricating the XYZ-axes and extruder gears are found in the Maintenance Guide.

Refer to the Maintenance Guide for recommendations on maintenance schedule.

Method 1 - Brush

- Heat the hot end to soften the material.

- Brush and wipe the tip of the nozzle to remove burnt material.

Method 2 - Manual Extrusion

- Push the lever of the extruder to release the filament.

- Bring the hot end to extrusion temperature.

- Manually push the filament towards the hot end and see if that extra pressure unblocks the nozzle.

- Look for impurities in the extruded material. Feed the filament until the extrudate is clean. Otherwise, the nozzle will clog again shortly.

Method 3 - Hot Pull

The impurity clogging the nozzle may be bigger than the nozzle size, so it will not go through while unclogging. This method consists of dislodging the clog from the top.

- Push the lever of the extruder to release the filament.

- Bring the hot end to extrusion temperature.

- Remove the filament from the extruder.

- Cut 200 mm of fresh material. Make sure that the cut is as straight as possible.

- Insert the segment of filament all the way through the nozzle and push until it is not possible.

- Firmly and quickly pull the filament out.

- Cut the extremity of the filament and repeat the pulls until the filament comes out without any residue.

Method 4 - Cleaning Kit

Be careful while performing this method. The risk of burning yourself on the hot end is high. This method is unsafe for high-temperature filaments.

How to use the cleaning kit:

- Wear gloves to protect yourself against heat and burns.

- Bring the hot end to extrusion temperature.

- Retract/remove the filament if you can.

- Use a needle that is the same size as your nozzle or slightly smaller.

- With a pair of pliers, carefully insert the needle or guitar string into the nozzle opening and move it back and forth, breaking through and removing the clogged material.

Unremovable Clog

If you have tried these methods without success, the heater block assembly must be swapped with a new one.

AON3D does not recommend swapping nozzles on the heater block assembly, as this can be harmful and cause severe burns. In addition, a wrongful installation can lead to print defects and extrusion issues.

For this reason, nozzles can only be purchased as a part of the heater block assembly.

- Home the machine XYZ.

- Lower the bed by 200 mm.

- Move the suspected toolhead toward the center.

- With a mirror and sharpie marker, make a mark on the pulley and motor shaft. See the picture below as a reference.

- Manually force the toolhead left and right.

- Using a mirror, check if the mark on the pulley is offset versus the motor shaft. If the pulley slips on the shaft, you will see that the line across the pulley and shaft is broken.

The heatbreak is designed as the point of failure in case of a crash between the toolhead and the printed part or the bed - it protects the motion system from damage. Selling the heater block assembly as an assembly ensures that the heatbreak will function as intended and prevent other complications that can happen with an improperly installed heatbreak.

If your heatbreak snapped during a print, you might have a threaded section left in the cooling block. To remove the length of heatbreak stuck in the cooling block assembly, you can use vice grips to hold onto the broken part and take it out. If you are unsuccessful, you use a screw extractor.

This component may have to be replaced if the heatbreak cannot be removed from the cooling block. Reach out to help@aon3d.com for further assistance.

We do not have a recommendation for a UPS for the AON-M2 series. Because of the machine power requirements, a suitable UPS would be massive and expensive. However, you may contact Eaton to help you select one.

Note that if there is a power outage during a print, it will cancel the ongoing print.

Adding a cooling fan is not currently supported on the AON-M2 series.

We use external cameras to monitor our prints in our print farm. The cameras are placed outside the machine, so there are no heat requirements.

Here are our recommendations:

- Wyze Cam v2

- Eufy Solo IndoorCam P24

The machine is fairly well enclosed, and most customers just run it in a well-ventilated room per local OHSA requirements without additional setup. The machine has a single port that may be used for extraction post-printing (would not want to steal heat from the chamber during the print), with a few customers using a 3rd party BOFA unit or their facility’s ventilation for this. We recommend referencing the material’s SDS sheet to see if additional ventilation is required.

For reference, we print quite a few experimental filaments and run a bank of ventilation hoods in our print farm.

In your Simplify3D® print process, navigate to Scripts, then Tool Change Script, and copy-paste the following script into the dedicated section:

{IF OLDTOOL=0} T1

{IF OLDTOOL=0} M109 S240 T1 ;heat right tool to 240C before moving

{IF OLDTOOL=0} M104 S200 T0 ;cool left tool

{IF OLDTOOL=0} G91 ;relative mode

{IF OLDTOOL=0} G1 X-60 F20000 ;move T1 tool head to wipe

{IF OLDTOOL=0} G1 X60 F20000 ;move T1 tool head to wipe

{IF OLDTOOL=0} G1 X-60 F20000 ;move T1 tool head to wipe

{IF OLDTOOL=0} G1 X60 F20000 ;move T1 tool head to wipe

{IF OLDTOOL=0} G1 E5 F300 ;prime 5

{IF OLDTOOL=0} G1 E1 F60 ;purge 1

{IF OLDTOOL=0} G92 E0 ;reset extruder

{IF OLDTOOL=0} G90 ;absolute mode

{IF OLDTOOL=1} T0

{IF OLDTOOL=1} G91 ;relative mode

{IF OLDTOOL=1} M109 S260 T0 ;heat left tool

{IF OLDTOOL=1} M104 S180 T1 ;cool right tool

{IF OLDTOOL=1} G1 X60 F20000 ;move T0 tool head to wipe

{IF OLDTOOL=1} G1 X-60 F20000 ;move T0 tool head to wipe

{IF OLDTOOL=1} G1 X60 F20000 ;move T0 tool head to wipe

{IF OLDTOOL=1} G1 X-60 F20000 ;move T0 tool head to wipe

{IF OLDTOOL=1} G1 E5 F300 ;prime 5

{IF OLDTOOL=1} G1 E1 F60 ;purge 1

{IF OLDTOOL=1} G92 E0 ;reset extruder

{IF OLDTOOL=1} G90 ;absolute mode

Feel free to modify the temperature parameters (Snnn) to suit your needs for lines 2-3 and 15-16.

For more information, see our Program Codes documentation.

Materials

While our machine is an open material solution, it is always best to ensure that you are sourcing your material from reputable, high-quality vendors.

Consistent filament diameter is one of many important quality factors. Inconsistent filament diameters result in extrusion inconsistencies and filament getting stuck in the feed path, leading to filament snapping.

AON3D sells pre-validated, high quality materials at market prices. To purchase materials or receive recommendations, contact us at help@aon3d.com or browse our validated materials in the Material Guides section.

A filament drying solution requires active heating to pull the moisture from the filament. The drying solution must reach temperatures of at least 150°C to dry the high-performance materials, such as PPSU, PEEK, and ULTEM™. Commodity-grade materials (such as ABS and ASA) require temperatures of at least 80°C.

In the AON3D print farm, we use a Quincy Model 20 Lab oven with a desiccant pack at the bottom for the best results.

For more information, see our Filament Drying and Moisture Control page.

While not in use, filament should be kept in an airtight container with desiccant packs or in a filament drying solution. For more information, see our Filament Drying and Moisture Control page.

No, the enclosed chamber of the AON3D printers makes the environment too hot, causing the filament to soften in the feed path, which will hinder extrusion or cause the filament to break. You may also experience sections of overheating on the print.

Currently, we do not offer any PLA grade thermoplastic as part of our material catalog. Refer to the Material Guides for available materials.

Software & Graphical User Interface (GUI)

AON3D does not officially support the Ultimaker Cura slicing software. AON3D cannot guarantee that the Ultimaker Cura will not damage the AON3D machine and/or give the same print results as Simplify3D®. Cura has been observed to cause random print-stop errors. The G-code Cura generates contains blank lines, which causes the machine to stop.

To mitigate this, parse your G-code to remove the blank lines. This can be done quickly with a code editor, but it does add an extra step to your process.

Some users have been able to avoid this by restarting the machine between every print.

This error happens because there is cooled filament in the toolhead, causing the probe to be compressed and to read as “triggered.”

If your bed is not all the way at the bottom of the chamber, heat your toolheads, retract the filament by 20 mm, and then home the bed.

If the bed is all the way at the bottom, you may have to raise it manually a little before performing the homing sequence.

To manually raise the bed:

- Heat your hot ends and retract your filament 20 mm.

- Press the E-stop.

- Manually turn the left and right lead screws until the bed is raised off the bottom of the chamber by at least 150 mm.

- Release the E-stop.

- Home the machine.

Unfortunately, it is not currently possible to manually update the time on the printer interface. To change the time, you will have to connect to the internet, which should update once completed.

Reference our Program Codes documentation to browse recognized commands.

General

All orders for spares, materials, and consumables must be paid in advance. We accept:

- Wire transfer

- ACH

- Cheque

- Credit card via a secure payment link. (Note that this method has a 3.5% service fee.)

Let us know which payment method you prefer at the time of the order.

Refer to the Machine Inspection instructions.

AON3D was founded in 2015 by a team of 3 materials engineers from McGill university – Kevin Han, Randeep Singh, and Andrew Walker.

Contact our global direct sales team at sales@aon3d.com for product information and quote requests.

Contact our Customer Success team at help@aon3d.com for product information and quote requests.

The AON-M2 ships globally from its manufacturing facility in Montreal, Canada.

Our success plans offer additional guidance and support to help you succeed faster. Learn more here.

Send press inquiries to sales@aon3d.com and include any deadline information within your email to ensure that we tend to your request as soon as possible.

We are on the constant lookout for more talented people to join our ever-growing team. Visit our careers page to discover new and exciting career opportunities!

Browse our various help topics, or refer to the AON3D Customer Success page. Note that if you are not subscribed to a support plan, response times vary based on availability of our Customer Success Managers.

If you are note currently subscribed to a support plan, we invite you to explore the benefits of our plans and find out why more than 80% of our customers choose to subscribe.