Kimya PEKK-A

Arkema Kepstan® is a Polyetherketoneketone (PEKK) copolymer, commonly used where resistance to extreme environments is needed. Produced from Kepstan®, Kimya PEKK-A is an amorphous form of PEKK, providing ease of processing due to very slow crystallization rates and an overall low degree of crystallinity. Kimya PEKK-A filament offers good mechanical and insulation properties with high chemical resistance: temperature resistance, flame retardancy, and complies with RoHS & REACH standards.

Used for technical applications, PEKK-A is often considered as an alternative to aluminum, ideal for the aerospace and automotive industries where high strength-to-weight ratios are important.

Printing Difficulty: Intermediate

PEKK-A has been replaced by AON3D Readyprint™ PEKK-A. The print settings are different.

- Moisture Control

- Build Platform Adhesion

- General Process Settings

- Post-Processing

- Technical Specifications

- Troubleshooting

Moisture Control

PEKK-A is extremely susceptible to moisture uptake. Bubbles, popping noises, excessive oozing, and stringing may occur if it has been hydrated, see the Stringing section for more information.

The filament can be dried in a convection oven at 120ºC for at least 4-6 hours before processing and fed from a low humidity environment. When not in use, store in a sealed package or container with silica desiccant to inhibit moisture absorption. Properly dry the material before adjusting process parameters to obtain reliable and consistent results. Our filament dry storage and feed system setup prevents filament moisture uptake to keep the material printing process free of moisture, contact help@aon3d.com for more information.

For more information, see the Filament Drying and Moisture Control guide.

Build Platform Adhesion

For instructions on how to inspect the AON3D build plates, refer to the Inspect and Clean Build Plates procedure.

Garolite G-10 Build Sheet

PEKK-A prints best on the Garolite G-10 build sheet due to strong adhesion behavior while at recommended bed temperatures and clean removal once the build sheet is cooled down. The G-10 surface is sensitive to Z offset calibration and scratches or scuffs on the surface. For the best results, use a lower first layer speed, a higher the first layer extrusion temperature, and remove the parts gently after prints are complete to minimize damage on the build surface.

PEI Build Sheet Single Use (Multiple Uses With Nano Polymer Adhesive)

We recommend two methods of printing on the PEI build sheet:

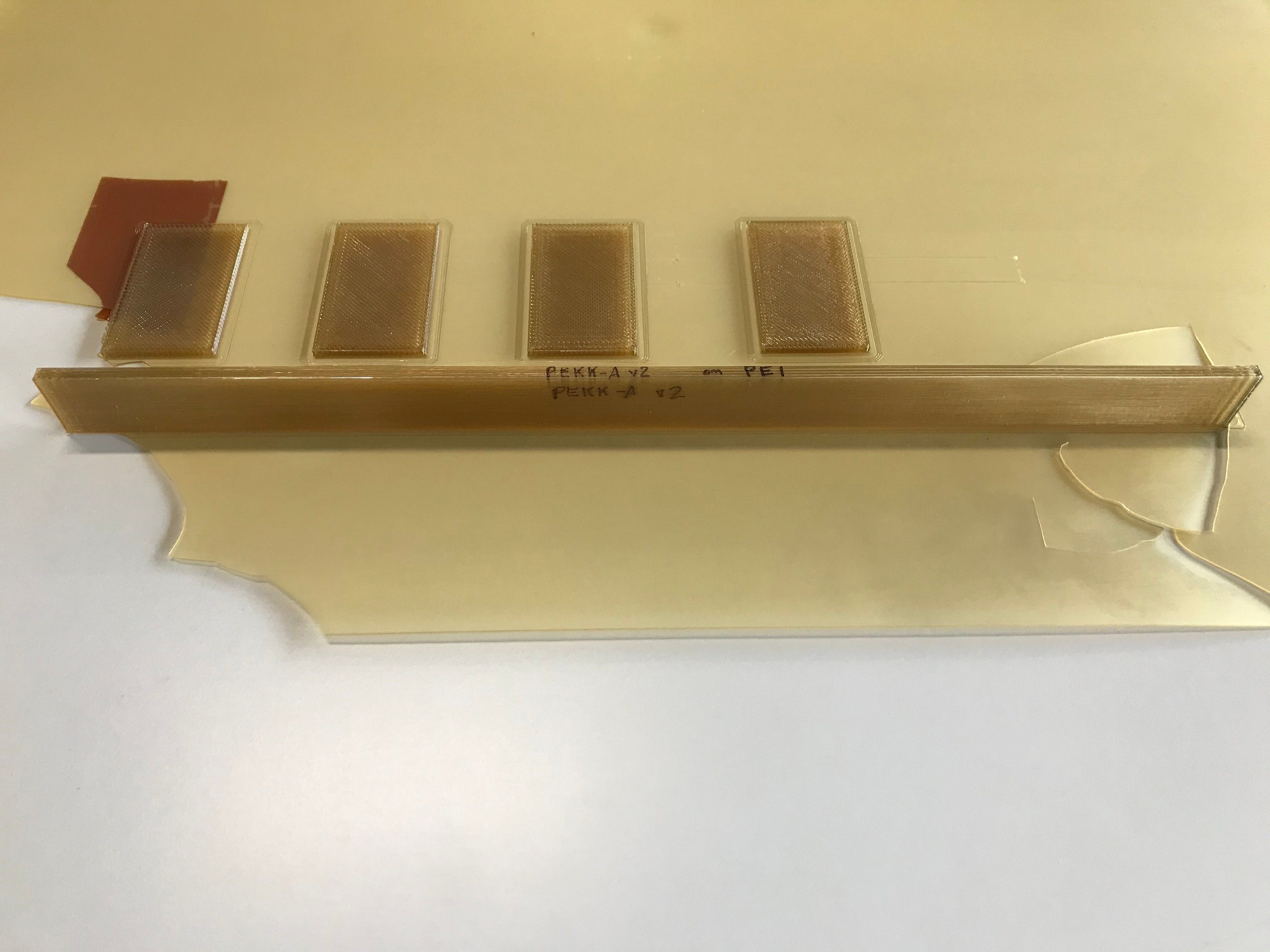

- Using the PEI build sheet only one time. The PEI build sheet offers the best adhesion to PEKK-A. Part removal after printing is often difficult to manage as the part and/or the PEI build sheet may get damaged as shown below. The part and the PEI build sheet may fuse, ultimately requiring post-processing to clean the part.

Large prints and/or warp-prone geometries may be ideal to print directly on the PEI build sheet for single-use applications. Doing so will ensure that the part does not warp after many hours of printing. The trade-off of a successful print would be the single-use application of the PEI build sheet. Part removal may be difficult and will require post-processing, but warping will not be a major problem during printing.

- Using the PEI build sheet multiple times but with the use of Nano Polymer Adhesive as a release agent. The use of Nano Polymer Adhesive facilitates part removal without damaging the part and/or PEI build sheet. A wide brim is recommended to reduce warping for warp-prone geometries due to the decreased first layer adhesion.

The PEI build sheet re-use capability is impacted by sheet deformation due to heat cycling.

CF-PEEK Composite Plate

PEKK-A prints well on the CF-PEEK composite plate. We recommend the CF-PEEK composite plate if re-usability is required. The CF-PEEK composite plate offers great re-use capability and maintains its integrity after several uses.

First Layer Adhesion

Start with a First Layer Height and First Layer Width of 100-150% for both and adjust until desired bed adhesion is achieved.

| First Layer Extrusion Temperature | First Layer Speed |

|---|---|

| 380-400ºC | 20-30 mm/s |

For more information, see the Build Platform Adhesion guide.

High-Temperature Build Plate

PEKK-A prints best on the High-Temperature Build Plate.

First Layer Adhesion

Part adhesion is very strong, often causing part and/or build platform damage during part removal. The first few layers may be printed with a reduced first layer height and lower extrusion temperature to decrease first layer adhesion. Fine-tuning the first layer may make the part release from the build platform easily while providing a stable base for the part.

Start with a First Layer Height and First Layer Width of 100-150% for both and adjust until desired bed adhesion is achieved.

| First Layer Extrusion Temperature | First Layer Speed |

|---|---|

| 320-350ºC | 20-30 mm/s |

For more information, see the Build Platform Adhesion guide.

High-Temperature Build Plate

PEKK-A prints best on the High-Temperature Build Plate.

First Layer Adhesion

Part adhesion is very strong, often causing part and/or build platform damage during part removal. The first few layers may be printed with a reduced first layer height and lower extrusion temperature to decrease first layer adhesion. Fine-tuning the first layer may make the part release from the build platform easily while providing a stable base for the part.

Start with a First Layer Height and First Layer Width of 100-150% for both and adjust until desired bed adhesion is achieved.

| First Layer Extrusion Temperature | First Layer Speed |

|---|---|

| 320-350ºC | 20-30 mm/s |

For more information, see the Build Platform Adhesion guide.

General Process Settings

For best results, process settings should be adjusted based on model geometry. If you require process development support, our Applications Engineering team can help! Send us a message at help@aon3d.com to consult with one of our Additive Manufacturing Specialists.

We recommend always printing PEKK-A fully amorphous due to its extremely slow crystallization rates and overall low degree of crystallinity. High degrees of crystallinity are almost impossible to achieve while printing PEKK-A; requires post-processing to increase the degree of crystallinity. The amorphous nature of PEKK-A allows for increased interlayer adhesion and internal stress management compared to other semi-crystalline materials. Crystallization-induced shrinkage is drastically reduced, decreasing the likelihood of warping and shrinkage.

Optimal extrusions are translucent and dark-honey. Stressed extrusions may appear opaque and light-honey. It is ideal to extrude at the lowest temperature in the highest chamber temperature possible. Use a nozzle size of at least 0.40 mm with lower printing speeds between 20-40 mm/s for optimal mechanical properties and print quality. Part warpage and/or deformation may occur if internal stresses are not sufficiently managed; induced stress by polymer shrinkage. Higher extrusion temperatures and moderate printing speeds help the polymer flow more easily, decreasing the accumulation of stress between each layer. Thus, interlayer welding strength increases but polymer degradation may occur from extremely high extrusion temperatures, especially if the printing speed is very slow.

| Setting | AON M2+ | AON-M2 2020 | AON-M2 |

|---|---|---|---|

| Extrusion Temperature | 320-400ºC | 320-400ºC | 320-400ºC |

| Bed Temperature | 120ºC | 150ºC | 150ºC |

| Chamber Temperature | 120ºC | 120ºC | 120ºC |

| Print Speed | 20-40 mm/s | 20-40 mm/s | 20-40 mm/s |

| Nozzle Size | 0.40-0.60 mm | 0.40-0.60 mm | 0.40-0.60 mm |

| Preferred Build Platform | Garolite G-10 Build Sheet | High-Temperature Build Plate | High-Temperature Build Plate |

Dual Extrusion and Support

There is currently no compatible support material for PEKK-A; prints require self-support. For easy support removal and good support top/bottom contact layer adhesion, use only 1 Upper/Lower Vertical Separation Layer. More than 1 separation layer may risk the supported region of the part to detach and warp.

For more information, see the Using Supports and Support Materials guide.

Sample Slicer Profiles

SuperSlicer

All AON3D-validated materials are available in the SuperSlicer configuration bundle. Refer to SuperSlicer Installation and Update to install and update the SuperSlicer software. Follow the instructions to update to the latest version to ensure you have access to all available materials.

Simplify3D®

Simplify3D® sample profiles for PEKK-A are available in the Downloadable Assets section.

Post-Processing

Allow all machine components to reach room temperature before proceeding further. Failure to allow components to cool down will result in thermal injury (burns) to personnel.

Shrinkage, deformation, and warpage due to thermal shock may occur from removing the part before letting the machine cool. Instructions for removing the part from the build platform and additional support material can be found on the Build Platform Adhesion and Using Supports and Support Materials guides.

PEI Build Sheet Single Use (Multiple Uses With Nano Polymer Adhesive)

PEKK-A prints may not separate easily from the PEI build sheet given a sudden impact. PEKK-A prints may separate easily from the PEI build sheet given a sudden impact if Nano Polymer Adhesive was used as a release agent. Damage to the part and/or the build platform may occur during part removal. The use of a spatula can facilitate part removal if needed.

CF-PEEK Composite Plate

PEKK-A prints may separate easily from the CF-PEEK composite plate by hand at room temperature. The use of a spatula can facilitate part removal if needed.

High-Temperature Build Plate

PEKK-A prints may not separate easily from the High-Temperature Build Plate given a sudden impact. Damage to the part and/or the build platform may occur during part removal. The use of a spatula can facilitate part removal if needed.

High-Temperature Build Plate

PEKK-A prints may not separate easily from the High-Temperature Build Plate given a sudden impact. Damage to the part and/or the build platform may occur during part removal. The use of a spatula can facilitate part removal if needed.

Technical Specifications

For more information on material safety and specific material properties, see the manufacturer’s website.

Physical Properties

| Property | Value | Test Method |

|---|---|---|

| Diameter | 1.75 mm, +/- 0.1 mm | INS-6712 |

| Density | 1.261 g/cm³ | ISO 1183-1 |

| Glass Transition Temperature | 159°C | ISO 11357-1 DSC (10°C/min - 20-410°C) |

| Melting Temperature | 308°C | ISO 11357-1 DSC (10°C/min – 20-410°C) |

| Heat Deflection Temperature @ 1.8 MPa | 172°C | ISO 75f |

| Melt Flow Index @ 380°C, 5kg | 37-47 g/10 min | ISO 1133-1 |

| Moisture Rate | <1% | INS-6711 |

*All data as reported by Kimya Technical Data Sheet as downloaded on 3/25/2021. Print conditions listed on the Technical Data Sheet.

Troubleshooting

Stringing

High temperatures are needed to optimally print PEKK-A. This makes stringing/oozing a common issue due to these high processing temperatures.

If stringing/oozing occurs even when properly dried and fed from a low humidity environment, slightly decrease the Extruder Temperature, increase the Retraction Distance, Coasting Distance, and/or the Retraction Speed.