> AON-M2 Series > Maintenance Guide > Preventive Maintenance > Inspect Linear Components and Lead Screws for Contamination

Inspect Linear Components and Lead Screws for Contamination

| Model | [•] AON M2+ (CE) | [•] AON M2+ (R-NZ) | [•] AON M2+ | [•] AON-M2 2020 | [•] AON-M2 |

| Category | [•] Preventive | [ ] Corrective | |||

| Frequency | [•] Daily | [ ] Weekly | [ ] Monthly | [ ] Yearly | [ ] As Needed |

Summary

The procedure that follows gives instructions on how to look for contamination and unwanted material on the linear rails, linear shafts and lead screws.

Clean components prevent:

- X, Y, and/or Z-axes binding.

- Loud noises when the axes are in motion.

- Unsatisfactory print layers.

Estimated time: 15 minutes

Tools

None required.

Parts Information

None required.

Personal Protective Equipment

| Qty | Description | Minimum Specification |

|---|---|---|

| 1 | Safety Eyewear | ANSI/ISEA Z87.1 |

| A/R | Nitrile Gloves | ISO 2859-1 or ASTM D6319 |

Prepare the Machine

Make sure that there are no prints on the build surface. Remove print(s) before the procedure that follows is started. Failure to do so can cause a collision and cause damage to the machine component(s).

- Home XYZ.

- Lower the Z-axis by 300 mm.

- Push the E-stop button.

- Open the build chamber door.

- Wait until the build chamber, build platform and hot ends are at room temperature.

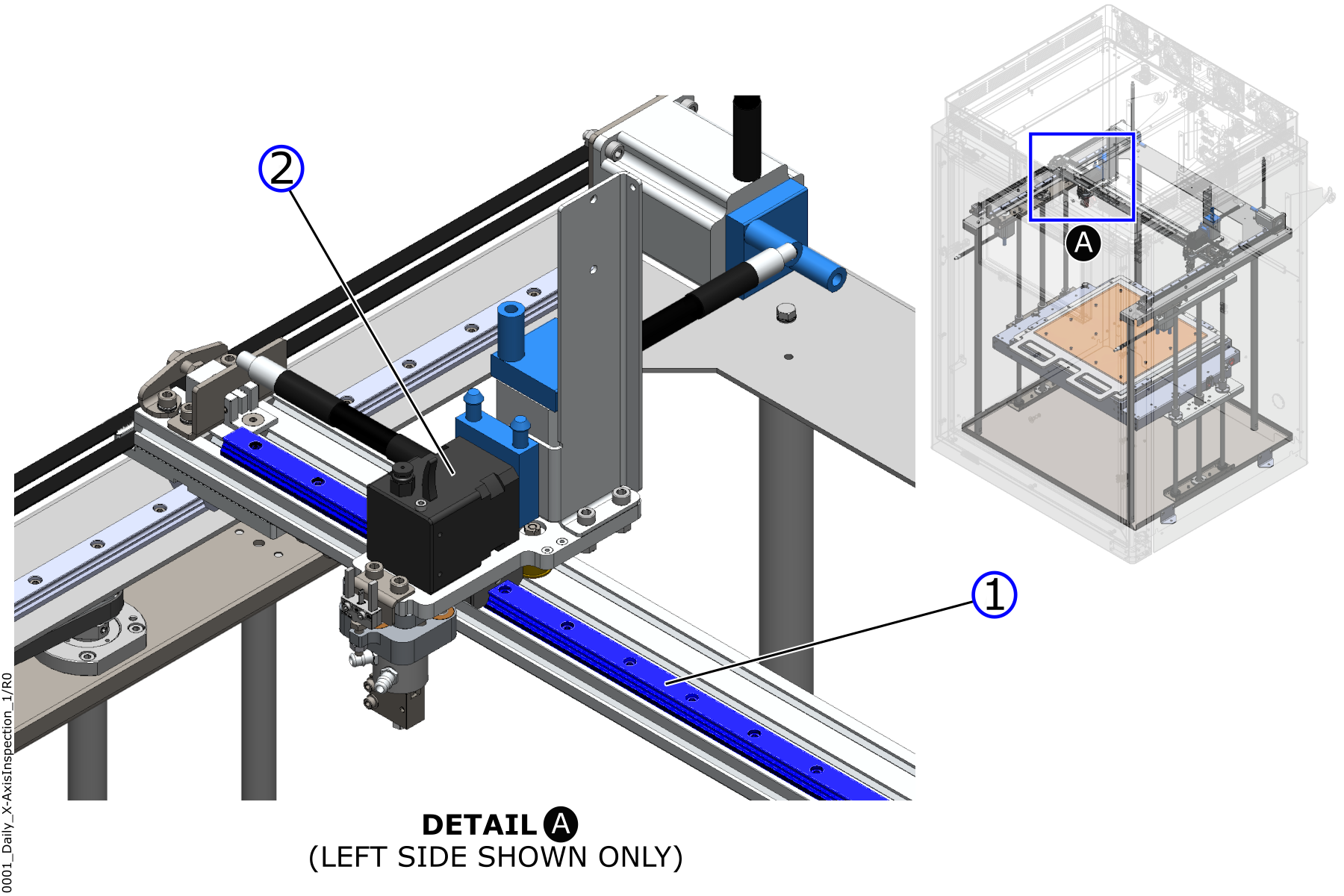

Inspect the X-Axis Linear Rail

Allow all machine components to reach room temperature prior to proceeding further. Failure to allow components to cool down will result in thermal injury (burns) to personnel.

- Manually move T0 (2) to the center of the the X-axis linear rail (1).

- Inspect the X-axis linear rail (1) surfaces for contaminants.

- Manually move T0 (2) to the left-hand side of the X-axis linear rail (1). Inspect X-axis linear rail (1) for contaminants.

- Manually move T1 to the center of the the X-axis linear rail (1).

- Inspect the X-axis linear rail (1) surfaces for contaminants.

- Manually move T1 to the right-hand side of the X-axis linear rail (1). Inspect X-axis linear rail (1) for contaminants.

- Remove all contaminates as necessary. Refer to Clean and Lubricate X/Y-Axes.

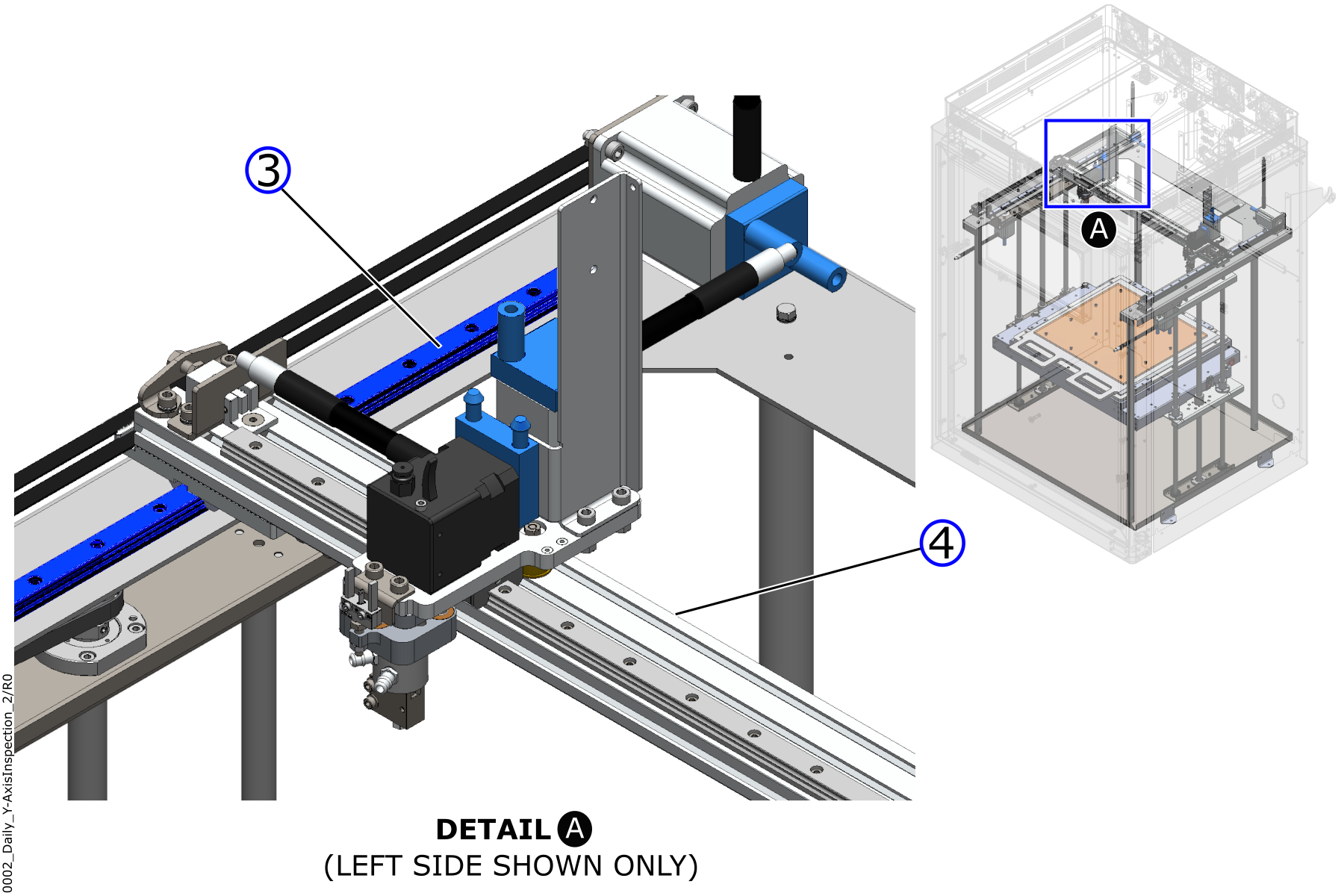

Inspect the Y-Axis Linear Rails

- Manually move the Y-axis gantry (4) to the rear of the build platform.

- Inspect the two Y-axis linear rail (3) surfaces for contaminants. Look for signs of contaminants such as liquids and/or dust.

- Manually pull the center of the X-axis gantry (4) to the center of the Y-axis.

- Remove all contaminates as necessary. Refer to Clean and Lubricate X/Y-Axes.

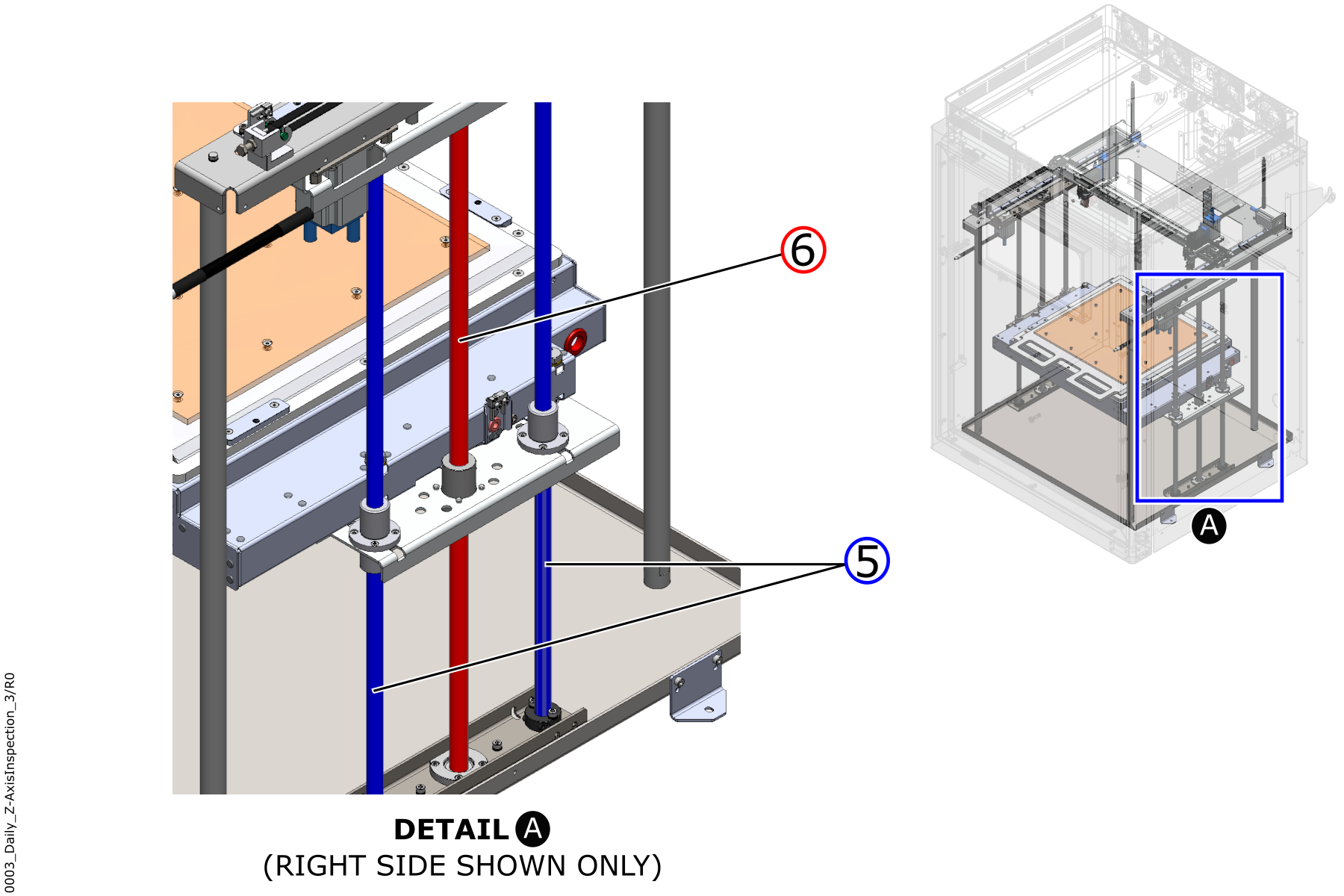

Inspect the Z-Axis Linear Shafts and Lead Screws

- Inspect the Z-axis linear shafts (5) and both lead screws (6) for contaminants.

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.

- Lower the Z-axis bed assembly to the bottom of the build chamber.

- Raise the Z-axis by 150 mm.

- Open the build chamber door.

- Push the E-stop button.

- Look for signs of contaminants.

- Remove all contaminants as necessary:

- For AON M2+ machines, refer to Clean and Lubricate Z-Axis (M2+).

- For AON-M2 and AON-M2 2020 machines, refer to Clean and Lubricate Z-Axis.

Test and Return to Service

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.