Clean and Lubricate Z-Axis (M2+)

| Model | [•] AON M2+ (CE) | [•] AON M2+ (R-NZ) | [•] AON M2+ | [ ] AON-M2 2020 | [ ] AON-M2 |

| Category | [•] Preventive | [ ] Corrective | |||

| Frequency | [ ] Daily | [ ] Weekly | [•] Monthly | [ ] Yearly | [ ] As Needed |

For instructions on how to clean and lubricate the AON-M2 and AON-M2 2020 Z-axis linear components, refer to the Clean and Lubricate Z-Axis procedure.

Summary

The procedure that follows gives instructions on how to clean and lubricate the Z-axis machine components found on the AON M2+ machine.

Estimated time: 60 minutes

Correctly lubricated Z-axis machine components will prevent:

- Friction between motion components.

- Contamination and/or debris on the Z-axis lead screws, rods, and/or lead nuts.

- Loud squeaks and vibration while Z-axis is in motion.

- Unsatisfactory print layers.

Tools

| Qty | Description | Specification |

|---|---|---|

| 1 | Wide Flexible Scrub Brush | N/A |

| 1 | Brass Brush | N/A |

| 1 | Applicator Brush | N/A |

| A/R | Degreaser | Spray Nine® |

| A/R | Rags | Lint-free |

| A/R | Isopropyl Alcohol | 99% |

Parts Information

| Qty | Part Number | Description |

|---|---|---|

| 1 | C-000745 | SuperLube Silicone Lubricating Grease with Syncolon® (PTFE) 400g/14.1oz |

| 1 | K-0999-015 | Z-Axis Lubricant Field Kit |

A Z-Axis Lubricant Field Kit (SKU K-0999-015) is available to purchase. This kit contains the AON3D-approved lubricant and brushes needed to maintain the lead screws. Reach out to our Customer Success team at help@aon3d.com to purchase the a Z-Axis Lubricant Field Kit.

Personal Protective Equipment

| Qty | Description | Minimum Specification |

|---|---|---|

| 1 | Safety Eyewear | ANSI/ISEA Z87.1 |

| A/R | Nitrile Gloves | ISO 2859-1 or ASTM D6319 |

| A/R | Face Mask | Respiratory |

Prepare the Machine

Make sure that there are no prints on the build surface. Remove print(s) before the procedure that follows is started. Failure to do so can cause a collision and cause damage to the machine component(s).

- Home XYZ.

- Open the build chamber door.

- Push the E-stop button.

- Wait until the build chamber, build platform and hot ends are at room temperature.

Clean Z-Axis Components

Clean the Bottom of the Z-Axis Linear Components

Wait until all machine components are at room temperature before you continue. Some machine components can be hot if the machine was recently used. Failure to do so can cause injuries.

- Apply the Spray Nine® degreaser on the bottom side of the components that follow:

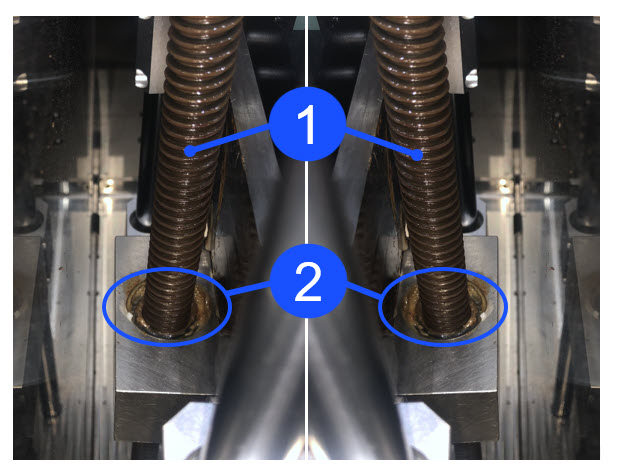

- Two leads screws (1)

- Two lead nuts (2).

- Let the Spray Nine® degreaser soak for 10 minutes.

- Remove the grease and unwanted contamination with the tools that follow:

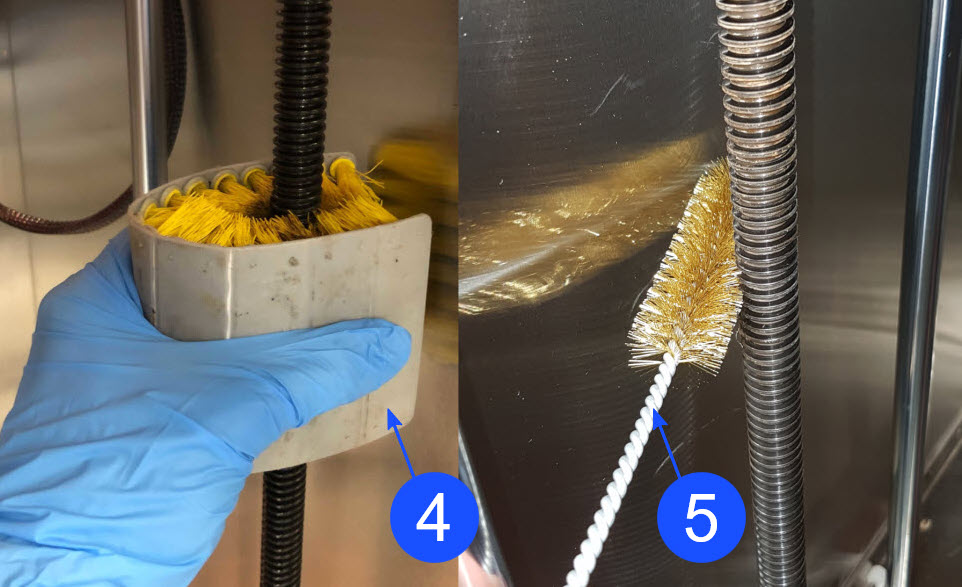

- Flexible scrub brush (4)

- Brass brush (5)

- Clean lint-free rags

- Isopropyl alcohol.

- Do steps 2 to 4 until the two lead screws (1) and the two lead nuts (2) are clean.

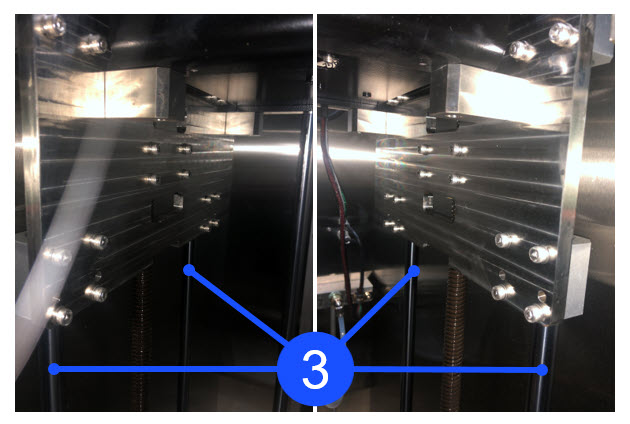

- Apply the isopropyl alcohol along the full length of the four linear shafts (3). Do not use degreaser.

- Use clean lint-free rags to clean the four linear shafts (3).

- Do steps 5 and 6 until the four linear shafts (3) are clean.

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.

- Lower the Z-axis to the bottom of the build chamber.

- Raise the Z-axis by 150 mm.

- Open the build chamber door.

- Push the E-stop button.

Clean the Top of the Z-Axis Linear Components

- Apply the Spray Nine® degreaser along the full length of the components that follow:

- Two lead screws (1)

- Two lead nuts (2).

- Let the Spray Nine® degreaser soak for 10 minutes.

- Remove the grease and unwanted contamination with the tools that follow:

- Flexible scrub brush (4)

- Brass brush (5)

- Clean lint-free rag(s)

- Isopropyl alcohol.

- Do steps 1 to 3 until the two lead screws (1) and the two lead nuts (2) are clean.

- Apply the isopropyl alcohol along the full length of the four linear shafts (3).

- Clean the four linear shafts (3) with clean lint-free rag(s).

- Do steps 5 and 6 until the four linear shafts (3) are clean.

Lubricate the Z-Axis Components

Only use SuperLube HT E.P. Grease with Syncolon® (PTFE) grease on the Z-axis lead screws and lead nuts. The only lubricant approved by AON3D for the Z-axis greased motion components is SuperLube Silicone Lubricating Grease with with Syncolon® (PTFE) grease. The use of non-approved lubricants can cause the Z-axis to bind, squeak, and/or vibrate. Non-approved lubricants can effect print quality.

Do not apply lubricants to four linear shafts (3). The AON M2+ uses greaseless linear bushings and must operate dry.

Do not operate the machine when the two lead screws (1) and two lead nuts (2) are not lubricated.

Lubricate the two lead screws (1) and two lead nuts (2) as follows:

- Use the applicator brush to apply a thin layer of SuperLube Silicone Lubricating grease along the full length of the two lead screws (1).

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.

- Lower the Z-axis to the bottom of the build chamber.

- Raise the Z-axis by 150 mm.

- Open the build chamber door.

- Push the E-stop button.

- If there is too much SuperLube Silicone Lubricating grease at the top and at the bottom of the two lead nuts (2), remove the grease with clean lint-free rag(s). Do not use isopropyl alcohol.

- Inspect the two lead screws (1) and the two lead nuts (2). Make sure there is a thin layer of SuperLube Silicone Lubricating grease where necessary.

- Use the applicator brush to apply a thin layer of SuperLube Silicone Lubricating grease along the full length of the two lead screws (1), if necessary.

- Close the build chamber door.

- Release the E-stop button.

- Home XYZ.

- Do steps 1 to 13, as necessary.

Test and Return to Service

- Open the build chamber door.

- Clean the build platform and build chamber, if necessary. Refer to the Clean Build Platform and Build Chamber procedure.

- Make sure that you remove all the tools from the build chamber.

- Close build chamber door.

- Home XYZ.