Inspect Coolant Level

| Model | [•] AON M2+ (CE) | [•] AON M2+ (R-NZ) | [•] AON M2+ | [•] AON-M2 2020 | [•] AON-M2 |

| Category | [•] Preventive | [ ] Corrective | |||

| Frequency | [ ] Daily | [•] Weekly | [ ] Monthly | [ ] Yearly | [ ] As Needed |

Summary

The procedures that follows gives instructions on how to inspect the coolant level in the coolant reservoir.

The correct coolant levels prevents:

- Machine components that operate too hot.

- Machine component failures.

- Unsatisfactory print quality.

Estimated time: 15 minutes

The coolant pump configurations are different between the AON M2+ (CE)/AON M2+ (R-NZ)/AON-M2 2020 and the original AON-M2 model. Instructions for both configurations are found on this page:

Tools

| Qty | Description | Specification |

|---|---|---|

| 1 | Screwdriver | Flathead, Large |

| 1 | Funnel | Small |

| A/R | Rags | Lint-free |

Parts Information

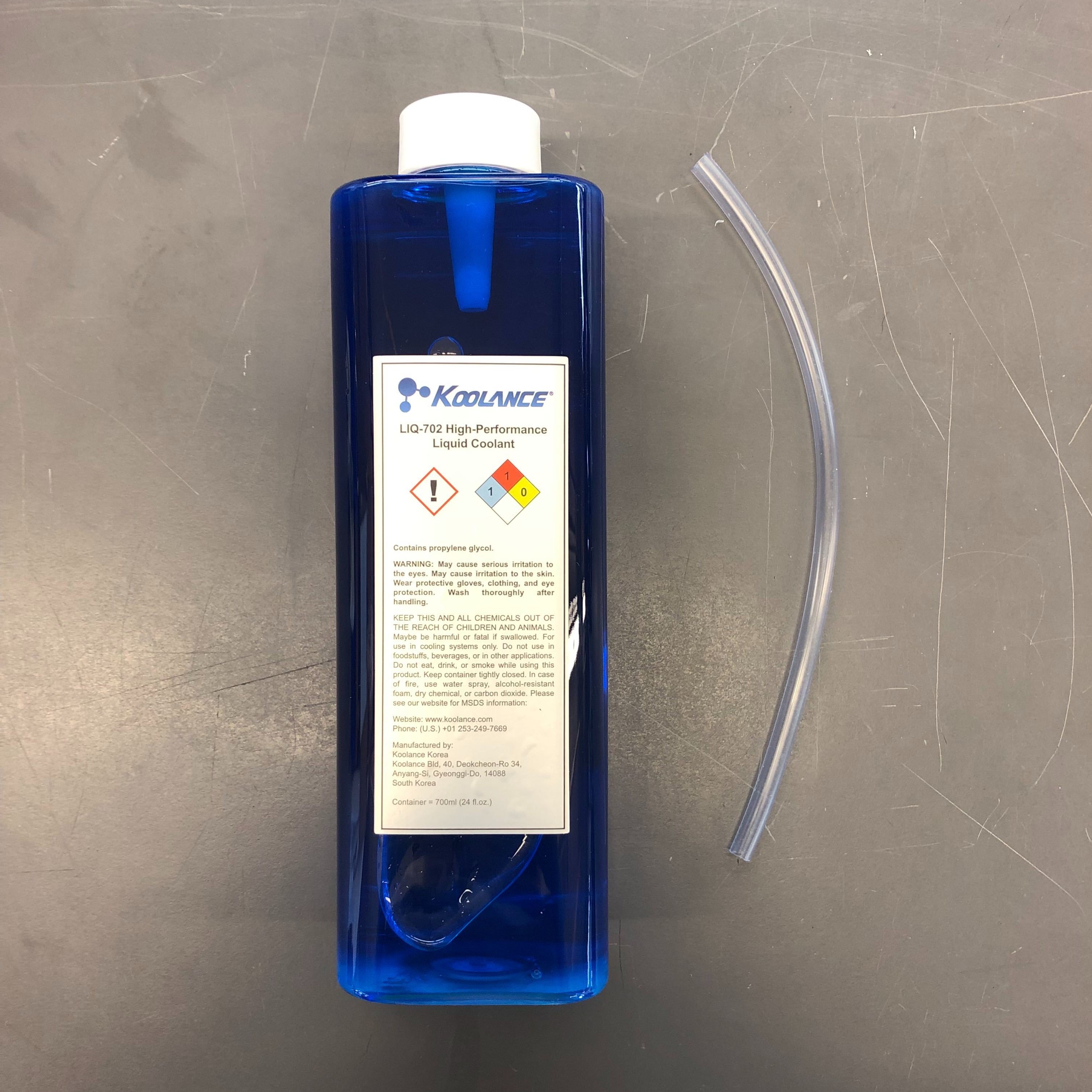

| Qty | Part Number | Description |

|---|---|---|

| A/R | A46067D6 | High-Performance Liquid Coolant, 700ml |

Reach out to our Customer Success team at help@aon3d.com for to purchase AON3D coolant.

AON3D uses coolants that can be different in color. All AON3D-approved coolants are interchangeable and are safe to use with AON machine component(s) and cooling circuit(s).

Personal Protective Equipment

| Qty | Description | Minimum Specification |

|---|---|---|

| 1 | Safety Eyewear | ANSI/ISEA Z87.1 |

| A/R | Nitrile Gloves | ISO 2859-1 or ASTM D6319 |

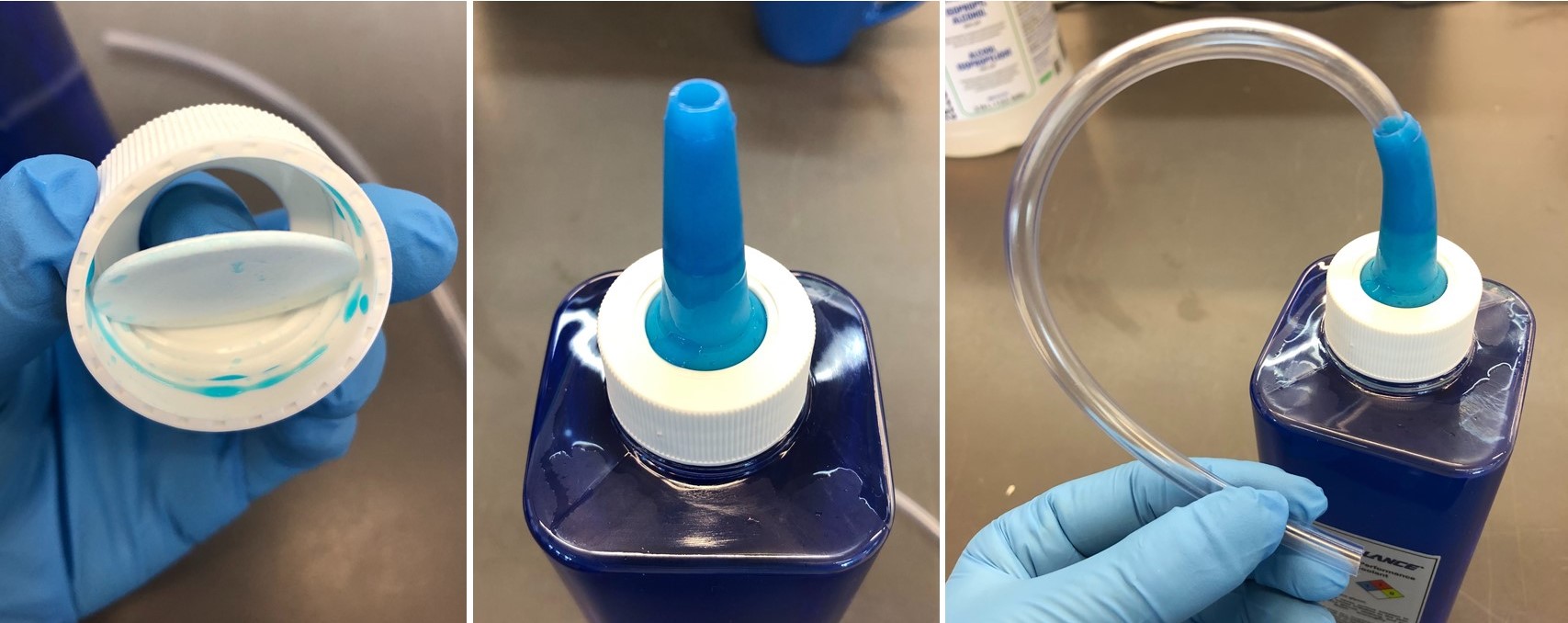

Prepare the Coolant Bottle

- Remove the coolant bottle cap to assemble the rubber spout onto the coolant bottle.

- Remove the rubber spout and set aside.

- Remove the plastic center cap. Do not discard the center cap as it can be reused to reseal the coolant bottle.

- Put the rubber spout upright on the coolant bottle opening.

- Secure the rubber spout assembly onto the coolant bottle with the cap.

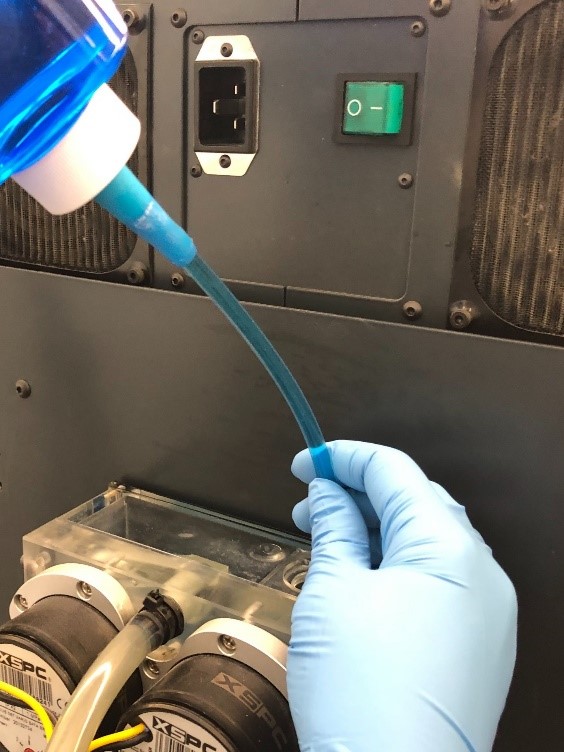

- Install the clear filler tube onto the rubber spout (AON-M2 application only).

The installation of the clear filler tube is for the AON-M2 application only.

Prepare the Machine

- Push the E-stop button.

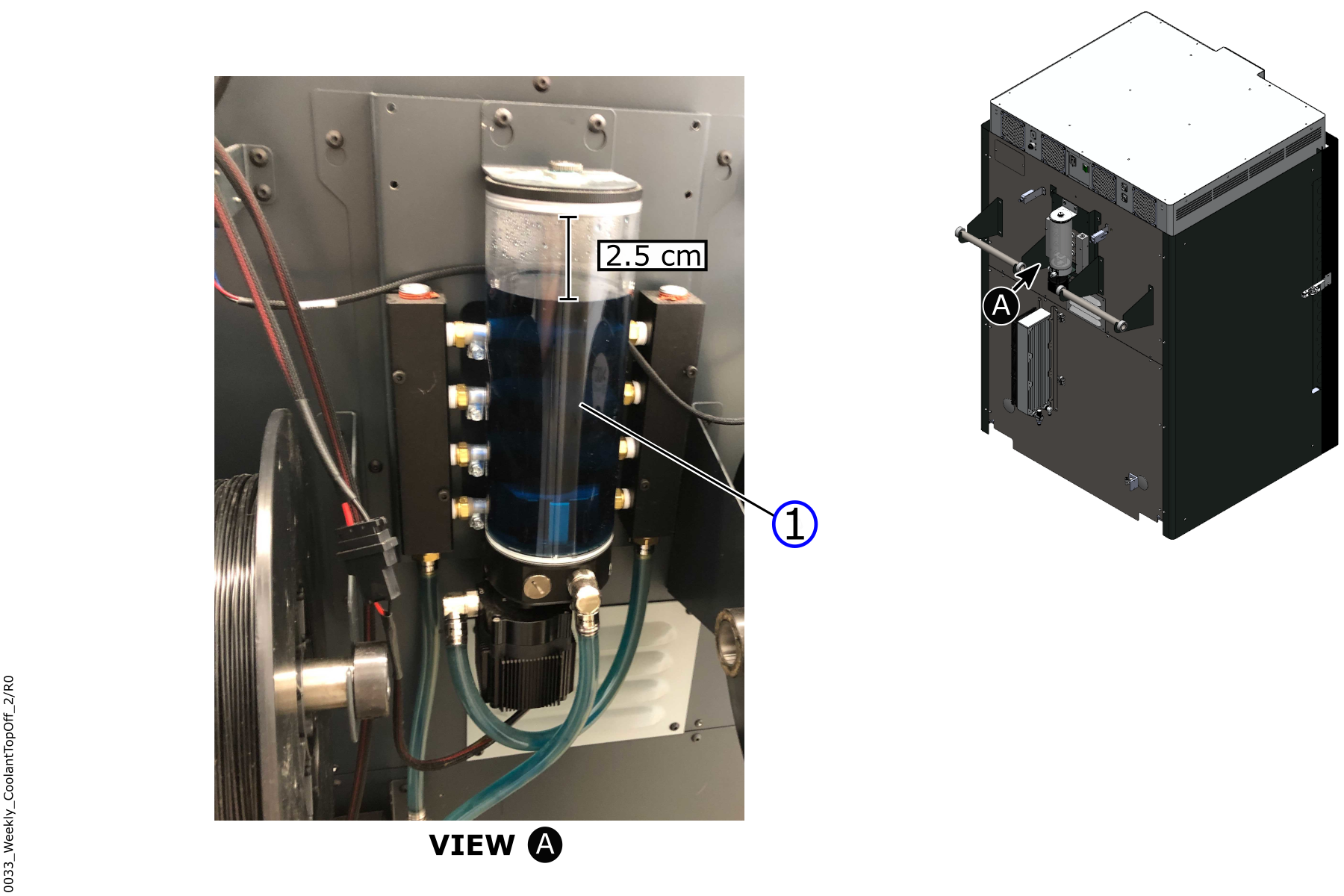

AON M2+ (CE), AON M2+ (R-NZ) and AON-M2 2020 Coolant Level Fill

Only use the AON3D recommended coolant. Failure to use the recommended coolant can cause damage to the machine component(s) and cooling circuit.

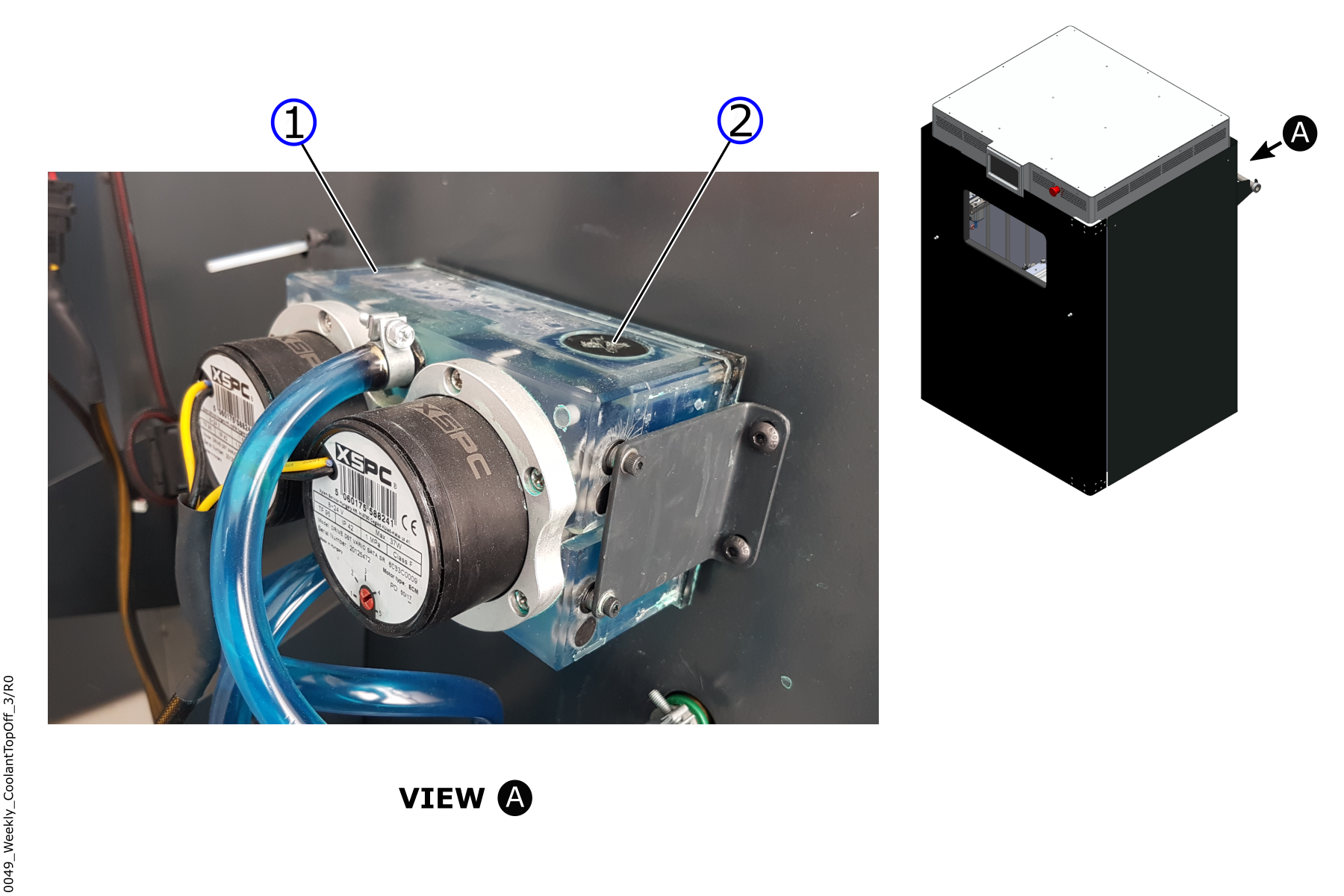

- Make sure that the coolant level in the coolant reservoir (1) is approximately 2.5 cm (one inch) from the top.

- If there is not sufficient coolant in the coolant reservoir (1), do steps 3 to 7.

- Use the large flathead screwdriver to remove the coolant reservoir cap (2).

- Put the tip of the small funnel into the coolant reservoir (1).

- Carefully add coolant in the coolant reservoir (1) until the coolant level is approximately 2.5 cm (one inch) from the top.

- If coolant overflows, clean with lint-free rag(s).

- Install coolant reservoir cap (2) onto the coolant reservoir (1).

- Use the large flathead screwdriver to tighten the coolant reservoir cap (2). Do not tighten too much.

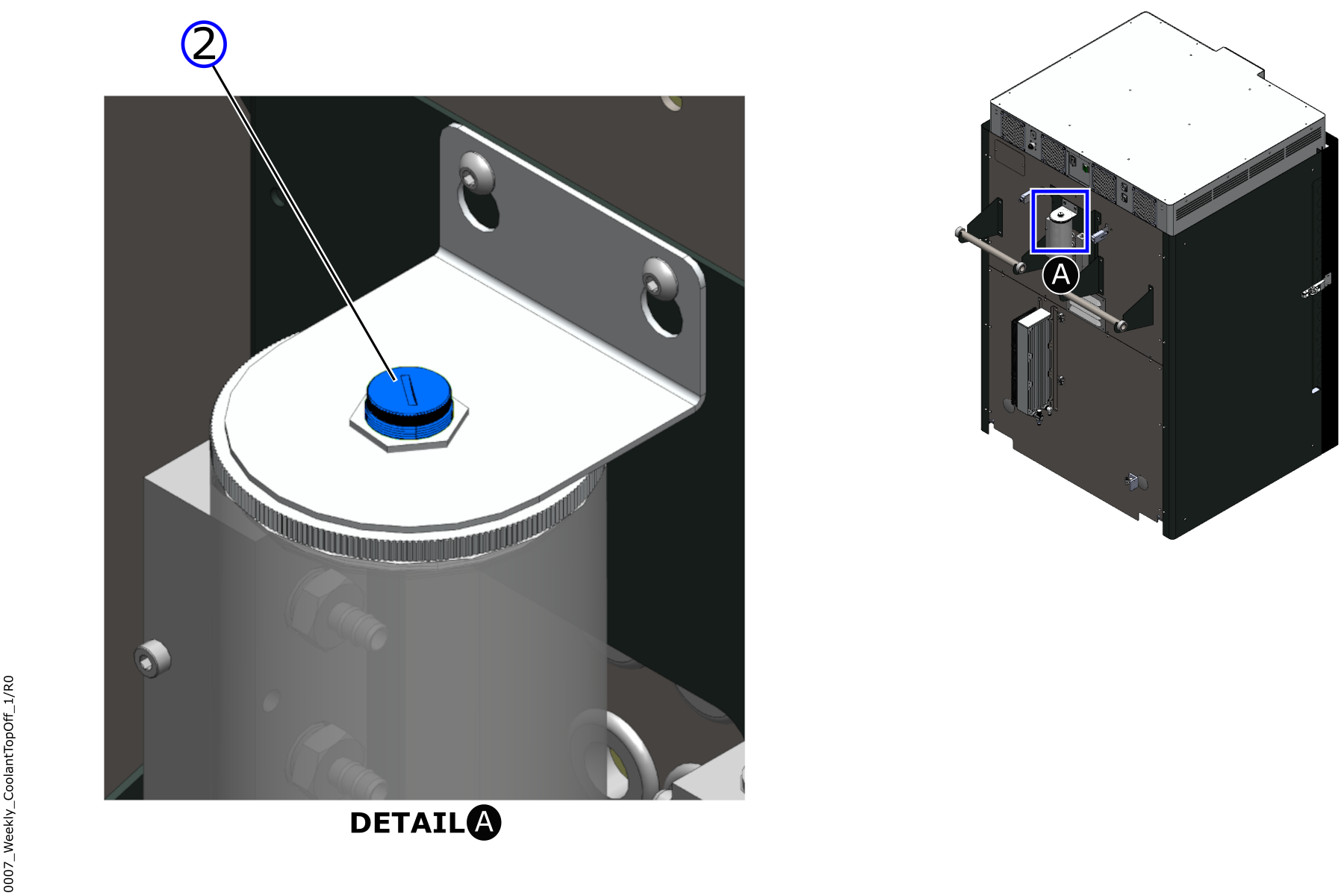

AON-M2 Coolant Level Fill

Only use the AON3D recommended coolant. Failure to use the recommended coolant can cause damage to the machine component(s) and cooling circuit.

AON3D now uses a different coolant solution from the one originally shipped with the AON-M2 machine. AON3D recommends to change the coolants when the recommended annual coolant flush is performed. A thorough coolant flush is necessary when a change in coolant types is done. Refer to Drain and Fill Coolant.

- Make sure that the coolant level in the coolant reservoir (1) is approximately 2.5 cm (one inch) from the top.

- If there is not sufficient coolant in the coolant reservoir (1), do steps 3 to 6.

- Use the large flathead screwdriver to remove coolant reservoir plug (2).

- Carefully add coolant in the coolant reservoir (1) until approximately 2.5 cm (one inch) from the top.

- If coolant overflows, clean with lint-free rag(s).

- Install the coolant reservoir plug (2) into the coolant reservoir (1).

- Use the large flathead screwdriver to tighten the coolant reservoir plug (2). Do not tighten too much.

Test and Return to Service

- Release the E-stop button.

- Home XYZ.

- Make sure that coolant does not leak on the outside of the machine while the cooling system is in operation.